Registered components for Paris Olympics 2024

Patent pending innovations

THE OLYMPIC CHALLENGE

"You don't need professors and engineers to know that bikes aren't fast. Every bike stays on the ground until an athlete doesn't feel confident enough to push it beyond the limits".

"We design the athlete's performance, not just performing parts"

"Performance in race is at the heart of everything we do in cycling. With some of the brightest minds in design, technology and engineering we redefine the balance between athlete and bike to achieve the best results in professional competitions with a motorsport approach".

"The primary focus lies in optimizing the athlete's performance enhancing the efficiency of his engine. It is not merely a drag reduction issue: we work on dynamic modeling to optimize the balance between multiple variables that influence the athlete's performance during the race".

The Performance Manifesto.

The design leader of TOOT Racing Romolo Stanco together with the Computational Mechanics group of the University of Pavia directed by the engineer Gianluca Alaimo with the supervision of Prof. Ferdinando Auricchio found the solution. The code name is X23. After gigabyte of data, hour of tests and simulations, the TOOT Racing design team developed a parametric digital model that involves frameset, components and athlete. This is the key to being faster and more efficient in the race.

THE STARTING POINT: Every athlete is our starting point. Our design team enhances features and potential while respecting the best comfort zone to obtain 110% performance.

ADAPTIVE DESIGN

Leveraging 3D modeling, the athlete's physical form has been transformed into a digital representation based on extensive testing within a simulator. This might come as a surprise, as it emphasizes that the athlete, not the bicycle, holds the dominant role.

The goal

The goal is to place the athlete in a situation where he feels seamlessly connected with his bicycle, which will be adjusted to perfectly match his optimal athletic movement without any compromise.

Designing perfection

By combining Horai with the Velogicfit dynamic 3D scanning system and the Occipital Structure Sensor scanner, the simulator is detached from the digital model. This enables TOOT Engineering designers to access the athlete's unaltered data as he pedals, allowing him to fine-tune the parameters that maximize performance based on individual characteristics.

Digital Twins

The digital twin system empowers the design team at TOOT Engineering to craft a virtual digital model of the cyclist engaged in his athletic performance at the highest possible level. This digital model can be adjusted, refined or reimagined, thereby offering the athlete actionable insights for potential performance enhancements.

Simulation as optimization

Thanks to the Horai® simulator's flexibility in adjusting various dimensional and load parameters, such as power and effort, the team can analyze copious amounts of data in the Aeromotion® Virtual Wind tunnel. With every variation in the athlete's position, these data provide insights about power, cadence, speed, frontal area and virtual CdA.

As in Formula1, the simulator is the perfect partner to find the best performance zone.

The dynamic 3D scanning by Velogicfit Motion Lab acquires biometric and dynamic data while pedaling. This is fundamental to continuously control efficiency.

The simulator allows you to increase pedaling resistance in order to exactly recreate the race situations, stresses and powers.

The simulator allows you to see and monitor your instantaneous cadence.

At the same time, the 3D Aeromotion sensor reads the frontal surface and CdA in real time, allowing you to understand how the position changes when power increases. This is much more reliable than wind tunnel data where the position is held without taking mechanical resistance into account.

Once the balance between power, aerodynamic efficiency and comfort zone has been found, the cyclist is 3D scanned on the simulator to create a virtual digital twin.

By crossing the parametric model of X23 frame and components and the athlete’s best performance position, the designers redesign the parts allowing the athlete to find the most efficient position on his X23.

THE PROCESS: Disruptive design, advanced materials, cutting edge technologies, Italian craftsmanship. An unique design and development process not only products.

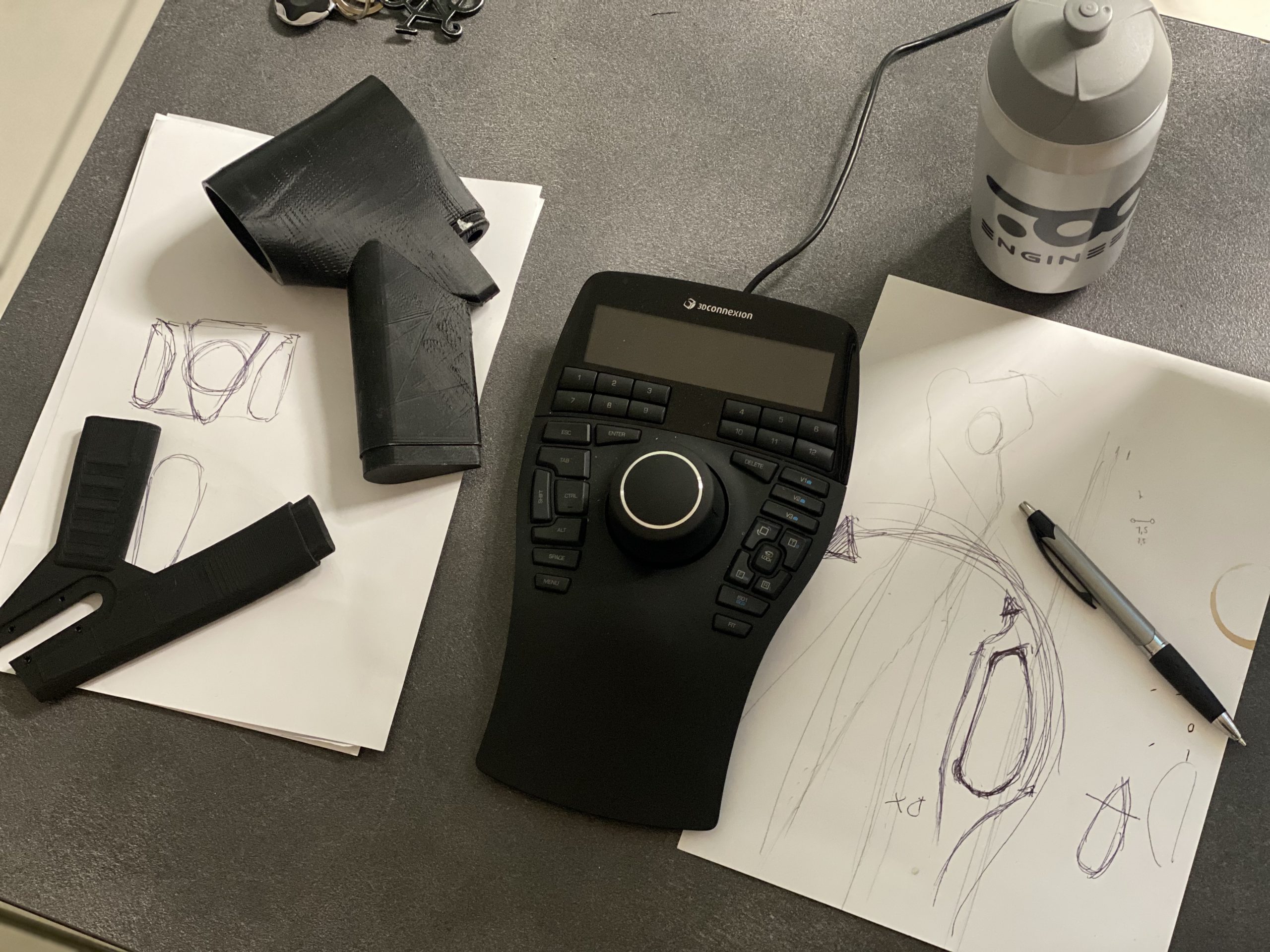

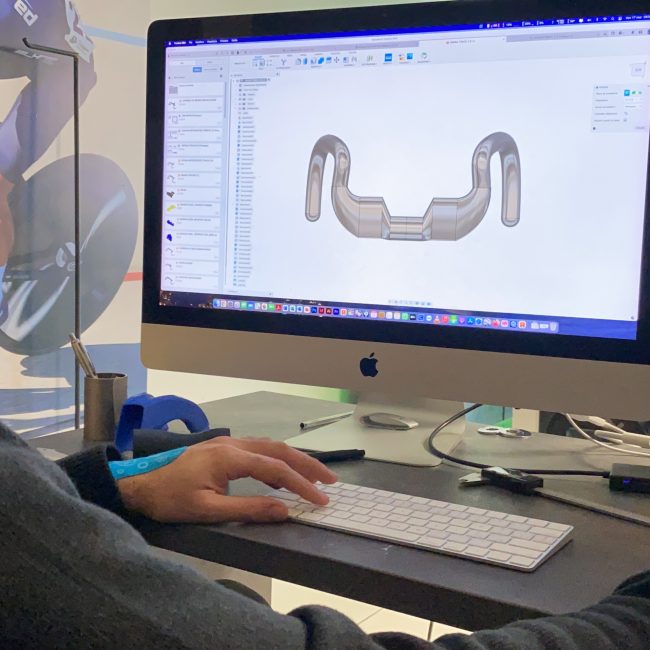

3D THINKING X 3D MAKING

The geometry of the front triangle of the frame and the rear seatstay triangle supports the pedaling gesture, becoming its most brute and direct extension.

BMX inspired

The size and unusual shape of the frame cradles is reminiscent of the design of BMXs. The BMX must have maximum reactivity, instant reaction speed and great handling combined with acceleration capable of enhancing the very high cadences of the athletes and great precision in the trajectories.

Totally 3D: designed and printed

The X23 frame is fully 3D designed to control the geometric parameters and deformations characterizing each of its parts. This is the reason why it is completely 3D printed and handwelded with advanced technologies like a MotoGP or a Formula 1 car. The frame is made of Scalmalloy® and AlscaZir® superalloys used in motorsport and aerospace thanks to their exceptional mechanical features. The 3D printing of a high-performance isotropic material allows the optimization of thicknesses and mechanical characteristics in a unique way compared to composites, allowing to match the behavior with the athlete's needs for each frame.

3D metals, not metal.

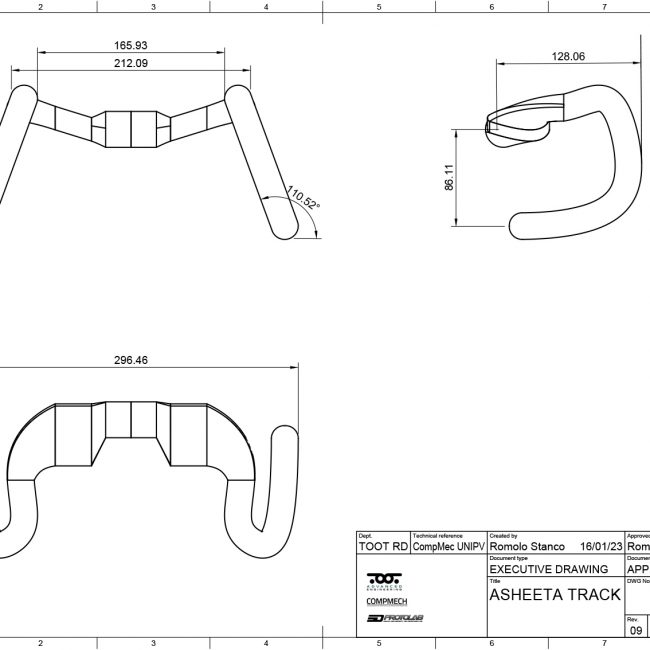

The X23 frame is 3D printed in Scalmalloy® but the TOOT Racing designers together with the COMPMECH Group engineers from the University of Pavia and the APWORKS technicians from the Airbus group developed different components using additive manufacturing technologies and different metals. The choice of material in fact depends on the characteristics that the design team seeks in the single component: seatpost and cockpit are made of titanium 6/4 to obtain dimensions - like in the SWANIGAMI pillar - that are unthinkable with composites, while ASHEETA is made of 316L steel and guarantees superior stiffness levels to any other handlebar on the market with a value of 381N/mm and a weight of 380g.

"Eagle's beak" T23 fork

The new T23 fork (in two lengths and rakes) contributes to the customization and can count on unique precision thanks to the proximity (only 47mm distance) of the two steering bearings. The design of the fork is also the result of an aerodynamic balance between the outwash effect of the speed airflow and the optimization of the turbulences generated by the front wheel.

Stiffness and traction optimization

"We can optimize the direction of the lines of force by balancing the 3D parametric frame design with the dynamic model of the athlete to improve traction and stiffness. Our engineers optimize the thickness and sizing of each part of the frame by designing the frame structures with dynamic FEA software, obtaining dedicated and unique 3D printed parts for every athlete".

Cutting edge technologies welded by humans

"The frame is made in 3D printed Scalmalloy® parts welded with forged and CNC machined AlSCaZir® parts in order to optimize every structural detail, enhancing the athletic gesture to a higher level. Furthermore, the tall and thin rear stays increase the resistance to compression (around 3G), helping to increase traction and almost completely eliminating sway and resonance".

THE AERO IMPROVEMENT: X23 SWANIGAMI is the bike with the lowest CDA of any current track bike. But this is not enough for our designers. The goal is to design a complex aerodynamic blended wing body to be faster. A low CdA bike is only the beginning to obtain the best aerodynamic performance.

AERO BIKE? NO. BE AERO

It's easy to think that the X23's aerodynamic quirks are the starting point for the entire bike design. It seems like an aerodynamically refined evolution of the THEFALCON, with a new wider fork and a flow deflector on the crown, the wide and high rear seatstay, the narrow tubes and the airfoil wing profiles at the limit of UCI rules.

You are off track.

Complexity is the answer

Of course, aerodynamics have a very important role in optimizing performance, but the X23 was born from the aerodynamic efficiency of the bike/athlete complex. X23 is the bike with the lowest frontal surface on the market (0.0398 m2 with a Cda of 0.199), but the real aero advantage comes from the position that the X23 allows you to maintain in the "comfort zone" with a measured watt saving of 30W at 60km/h compared to a traditional frame.

Not recipes for speed, numbers only

The X23 frame has a maximum ground clearance of 770mm. This is impressive considering the 700C wheel diameter. Stack is 483mm only: 15% lower than any other track frame of comparable size on the market. The athlete's position is high, almost like in time trials, the result of the "best position" on the HORAI® simulator. The simulations in CFD and in the virtual wind tunnel have demonstrated a drag reduction of over 4% and an improvement in the Cd of the athlete's body.

Born to be wind

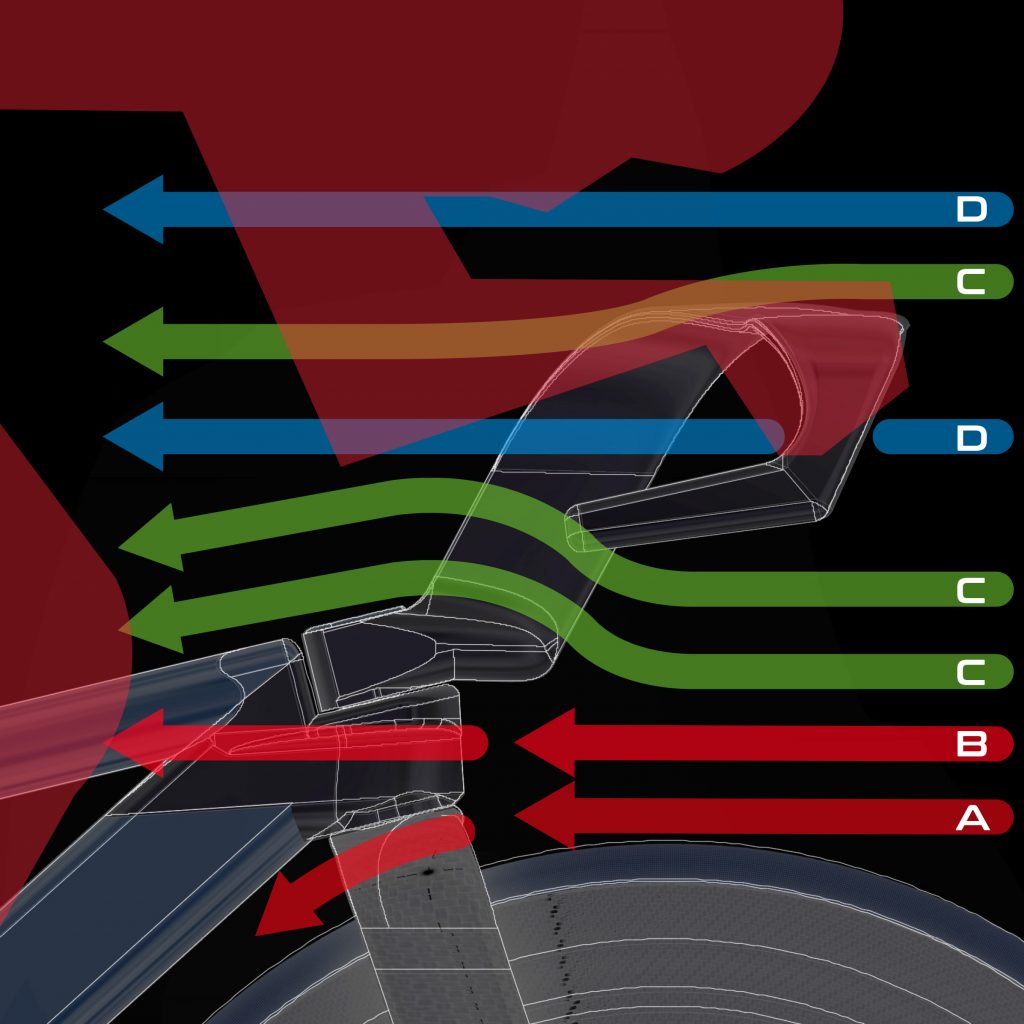

Following the wind tunnel tests in different TT position TOOT engineers defined a best bunch position to optimize the airflows and reduce drag. The athlete’s body together with the bike generates an empty channel under his body. We call this air duct T-DUCT®. The patent pending cockpit Swanigami is the key element in minimizing any element exposed to the speed airflow: the cockpit becomes a minimal support wing on which the athlete leans, transforming himself and the bike in a blended wing body.

Shape follows function

The T-shape of the cockpit with the super thin vertical pillar is the only physical element between the athlete’s body and the frame leaving a 300x300mm empty duct, drastically reducing the total drag. The simulation analysis indicates a watt saving of more than 25W at 60Km/h compared to a conventional solution with negative or 0° stem and a same width handlebar.

Is the exposed frontal bike surface including cockpit and wheels

Is the total drag of the wind exposed surfaces of the bike including components

Is the CdA calculated in the Virtual Wind tunned and confirmed by track test with pitot tubes with a 1,70 tall athlete, 69Kg

Is the aero duct between the frame and the athlete’s body

Is the aero advantage of the SWANIGAMI cockpit compared to a regular stem/handlebar measured on the same frame

Is the aero advantage of the X23 SWANIGAMI compared to a standard track bike with standard handlebar and drivetrain. Comparative test made with computational analysis on reverse engineered 3D models.

"Theory is never enough for those perfection addicted"

When I first chose T°RED and TOOT Engineering I was thriving for my own bike. Back in 2017 after trying the Manaia I thought that I could not have anything better than that. Then I had the chance to race and work with the team, and the Manaia SixDays came, and TheFalcon, the Peregrin and now the X23. I am perfectly aware that it might be hard to believe, but every time we get more and more to the point, beyond the limits. And it's not a sensation, it's a number driven information. Try it yourself and let me know.

PARAMETRIC COCKPITS: The TOOT Racing UCI registration allows to optimize the cockpit features to every needs. Stiffness, handling and ergonomics can be characterized by intervening on the project parameters thanks to advanced software and 3D printing.

COCKPIT, NOT HANDLEBAR

Don't underestimate your command post, your cockpit your main connection point between your bike and your hands.

While working on the seamless blending of athlete and bike, we developed and tested different cockpit solutions to offer an answer/proposal for every need coming out from the athlete tests and simulations. It might be a monococque rising the body as much as possible like the SWANIGAMI T-DUCT®, or the ASHEETA LOWSTACK stem and handlebar combination to stay lower: the answer will arrive from observation and numbers. There is no best solution. From an aerodynamic point of view, the difference between the two cockpits is not significant. Overall drag has a difference of less than 1%. However, TOOT Racing seeks the best performance in the athlete in a comfort zone where the only thought is to express oneself 100%. No driver can think of winning the 24 Hours of Le Mans if he doesn't feel good in his car.

Air is your enemy, use it.

This is how the TOOT Racing technicians and aerodynamicists "used" the air flow to remove aerodynamic weight from the athlete and save watts by making the shapes of the frame, components and body work together.

The “eagle’s beak” of the fork, together with the wedge shape of the headtube, has the task of directing the frontal flow laterally, moving the air away from the athlete’s legs. The angle on the Z axis of the “wedge airfoil shaped headtube” and the eagle beak above the fork is 30°. CFD data measures a reduction in air load on the legs of more than 30% compared to a standard fork and an airfoil headtube.

The “nose” of the SWANIGAMI and the upper wing of the cockpit have been designed to divert the primary flow of air downwards on the Y axis. The deviation is extremely smooth so as not to create turbulence but helps to accelerate the flow by decreasing its pressure due to the Venturi effect. In addition to a reduction in CdA, the geometries help the air flow to channel under the athlete’s body in the T-DUCT®, increasing the flow rate and volume of air which exerts less pressure on the body with an increase in overall aerodynamic efficiency .

The T-DUCT® is a system that generates an empty channel under the athlete’s body helping to reduce the frontal surface area and optimize air flow under the athlete’s body. The D flow areas are those that remain cleanest and encounter extremely small surfaces. The SWANIGAMI pillar is made up of an airfoil which opposes a maximum section to the flow of 11mm exactly like the seatpost. The maximum performance of the athlete and the least drag (regardless of the saddle height and stature of the athlete) is obtained when the athlete’s “nose” is 7-8 cm from the upper wing of the SWANIGAMI on the Y axis. Since SWANIGAMI It is designed for each athlete with parametric software and 3D printed, it is always possible to get very close to the optimal solution.

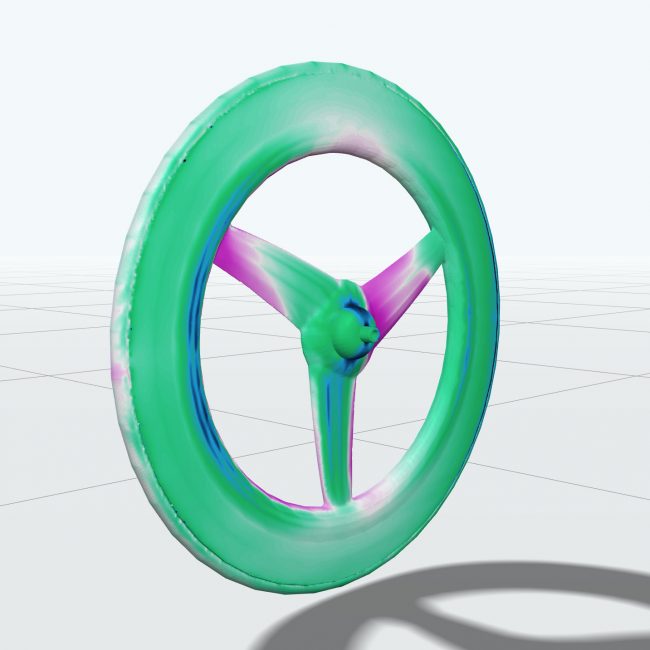

BEYOND THE OBVIOUSNESS. There are no "fast" wheels. We designed TOOT wheels to absorb as little of the athlete's engine power as possible. Smoothness of the bearings, stiffness, driveability, aerodynamics and low rolling resistance. The patented HOURGLASS profile and the thru-axle solution and clincher option are the way to increase your performance.

NO TIME WASTER ALLOWED

It would be ridiculous to say that the new Hourglass HG95 wheelset “is the fastest in the world”. We assure you: like a bike, the wheels do not turn by themselves, if you place them against the wall they remain still. But.

It allows you to drastically reduce absolute drag thanks to the design of the rim section optimized with CFD simulations and wind tunnel tests with the digital twin method. “It's as if the wheel isn't being hit by air” testers say, and so it is. The "hourglass" design (patented) of the rim creates an increase in air speed in the central part of the rim and consequently a decrease in pressure on the rim. This effect determines a significant reduction in aerodynamic weight and contributes to reducing CdA and making a high rim wheel extremely light and easy to handle. The second part of the “hourglass” cleans the flow towards the center of the wheel, optimizing the functioning of the spokes and the hub flange. The Compmech Engineers collaborated with the TOOT design team to balance aerodynamic optimization with increased stiffness.

Clincher optimized, tubular available

The Hourglass HG95 wheelset was designed for clincher use by increasing the internal rim channel compared to the ALIEN to accommodate 25mm (up to 30mm) clinchers: in the laboratory and in track tests this solution demonstrated lower rolling resistance and better rideability. However, it is also possible to have the HG95T with a tubular floor.

Watt saved with KATHENEENA® compared to a 1/8" track drivetrain

Test range: CdA 0,176 Speed 65Kmh gear ratio 4,12 | Power reduction 4%

Why the stayer?

The laboratory tests were carried out with advanced instruments as shown in the table above. A track test was carried out comparing the real data in motor paced track tests. The aerodynamic difference values that may be relevant in a track test to measure non-macroscopic differences become irrelevant if the CdA value becomes irrelevant. In the test behind a stayer bike at 79Kmh with gear ratio 5.36 (development 11.32 m) with KATHENEENA® the average power value stood at 250W NP cadence 114RPM (gear 118x22). With standard drivetrain the NP value with the same metric development data exceeds 280W NP with a percentage difference of 14%

IT'S NOT GAINING, IT'S NOT LOSING. Marginal gain is a misnomer. Nobody makes you earn anything, nobody increases your speed for anything. But "not losing" watts is the primary purpose of the new KATHEENEENA transmission. More than 5% advantage over a conventional drivetrain. We don't create speed but we know how to allow you not to lose it.

KATHENEENA® DRIVETRAIN. WATT SAVER

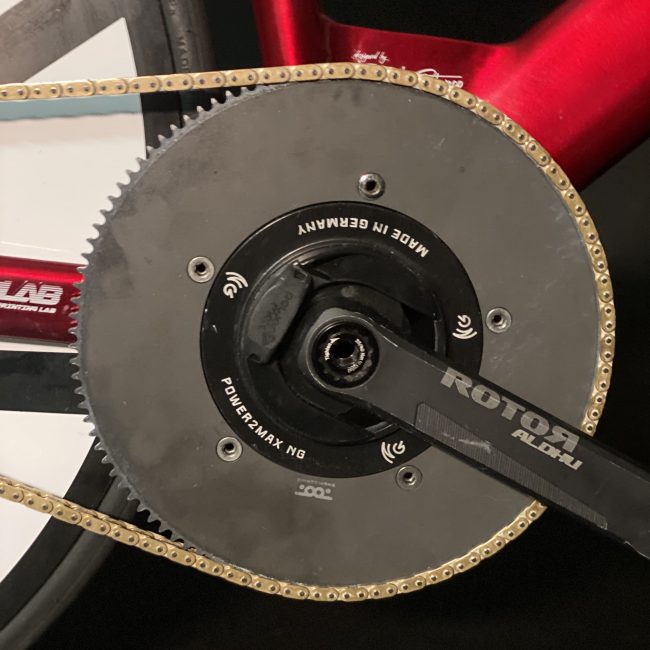

The transmission is another element of large power losses due to mechanical friction. Thanks to a test bench and the collaboration of DID chain and Csoltmester, TOOT engineers compared different chain and chainring solutions.

Patented by TOOT Racing, developed with D.I.D

The Japanese technicians have developed a chain with a pitch reduced by 65% compared to a 1/8" track chain and very short links: the polygonal effect is reduced, transmission between chain and gears improves 19% reducing overall friction. The work was done in partnership with Csoltmester who developed dozens of solutions for gears, tooth geometries, chainrings, pinion materials (including Ergal) and surface treatments with an exclusive lubrication.

Same watts, more speed...

The X23 Katheneena transmission almost doubles the number of gear teeth for the same circumference. A 60x15 becomes a 109x27 and the comparison test returns a reduction in contact friction of 4%. X23 Katheneena also creates a significantly greater flywheel effect than a 1/8” drivetrain improving overall drivetrain efficiency. KATHENEENA's performance is not legitimate only from tests carried out at the University of Pavia.

...more speed, less friction

The drivetrain patented by Bianca Advanced Innovations was successful in a discipline where the stresses on the transmission elements are much higher than in a track race. Giuseppe Atzeni won the Swiss Stayer National Championships with KATHENEENA. Stayer or demi-fond is a discipline in which speeds of almost 90km/k are reached for an hour of racing behind the motorbike: temperatures and mechanical stresses of the transmission test durability, resistance to effort and fatigue beyond all limits, allowing the optimization of treatments, ratios, chain tension and lubrication systems.

Example Title 1

Example Title 2

Example Title 3

Example Title

Example Title

Example Title

Example Title

Example Title

THEFALCON 300

THEFALCON 400

THEFALCON 300 PURSUIT

THEFALCON 400 PURSUIT

X23 PURSUIT

HORKOKHAN STAYER BIKE

CULEBRA TITANIUM SEATPOST

Romolo Stanco after his experiences at the CNR of Lecco, accepts the challenge of creating in Italy a lab that develops products from innovation and research projects.

Thesignspeaking.com

Romolo Stanco who directs TOOT Engineering works on exclusive manufacturing processes that combine technology and craftsmanship.

Road Bike Action

Knowledge comes from research, tests, relationships with pro–cyclists with deep competences and design abilities in order to create something new.

Gearminded.com