Total efficiency revolution, speed proven, championship winner.

First 3D printed metal track frame to win championships. Still winning. Still pioneering.

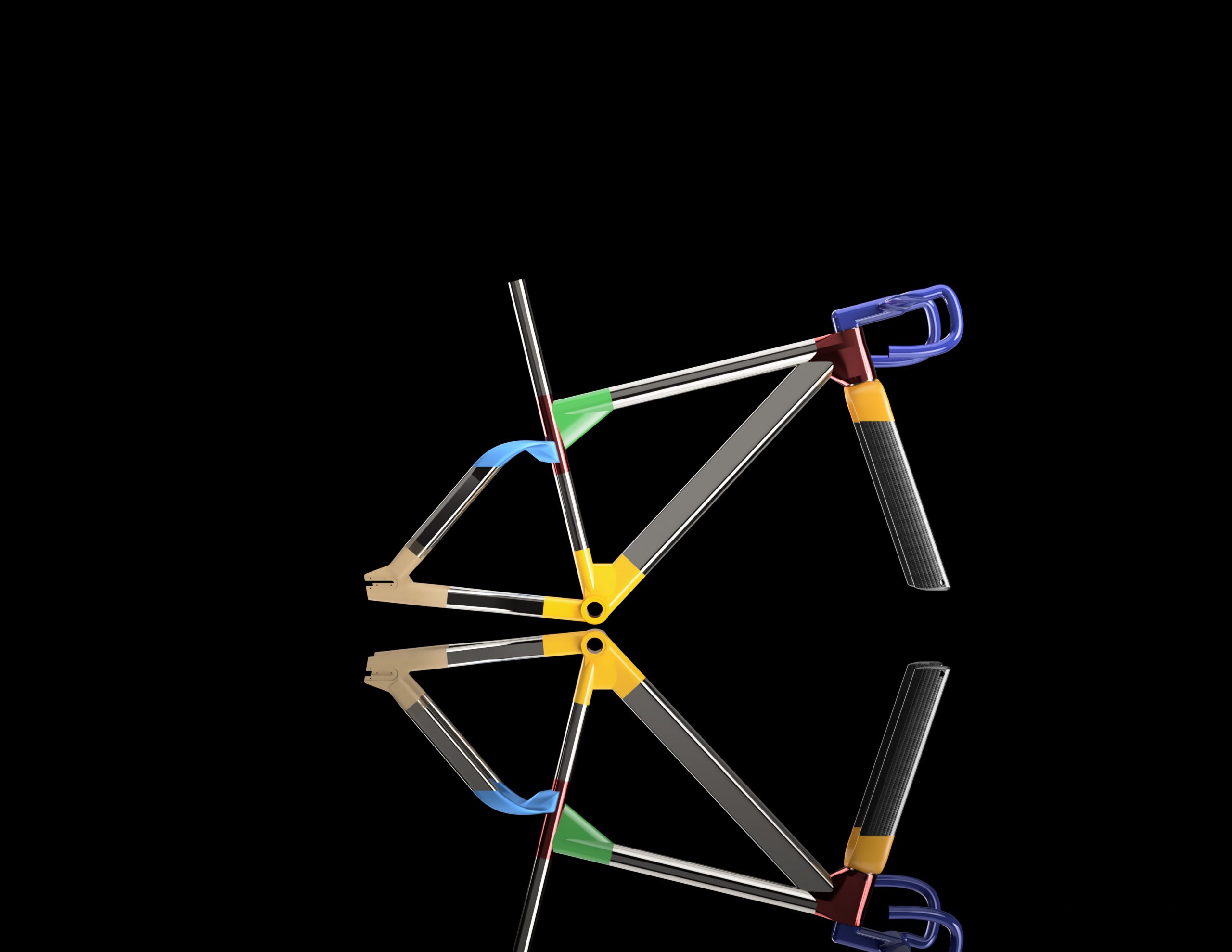

Every athlete’s dynamic equilibrium takes metallic form. THEFALCON400 – where instant reactivity meets devastating progression. LSST (Low Stack Small Triangles) geometry that transforms every input into pure acceleration.

Developed with Aaron Gate and internal team: World Champion experience applied to geometry and mechanical characteristics that make THEFALCON400 unique.

2025: James Gardner conquers New Zealand National Omnium. TOOT design continues to dominate.

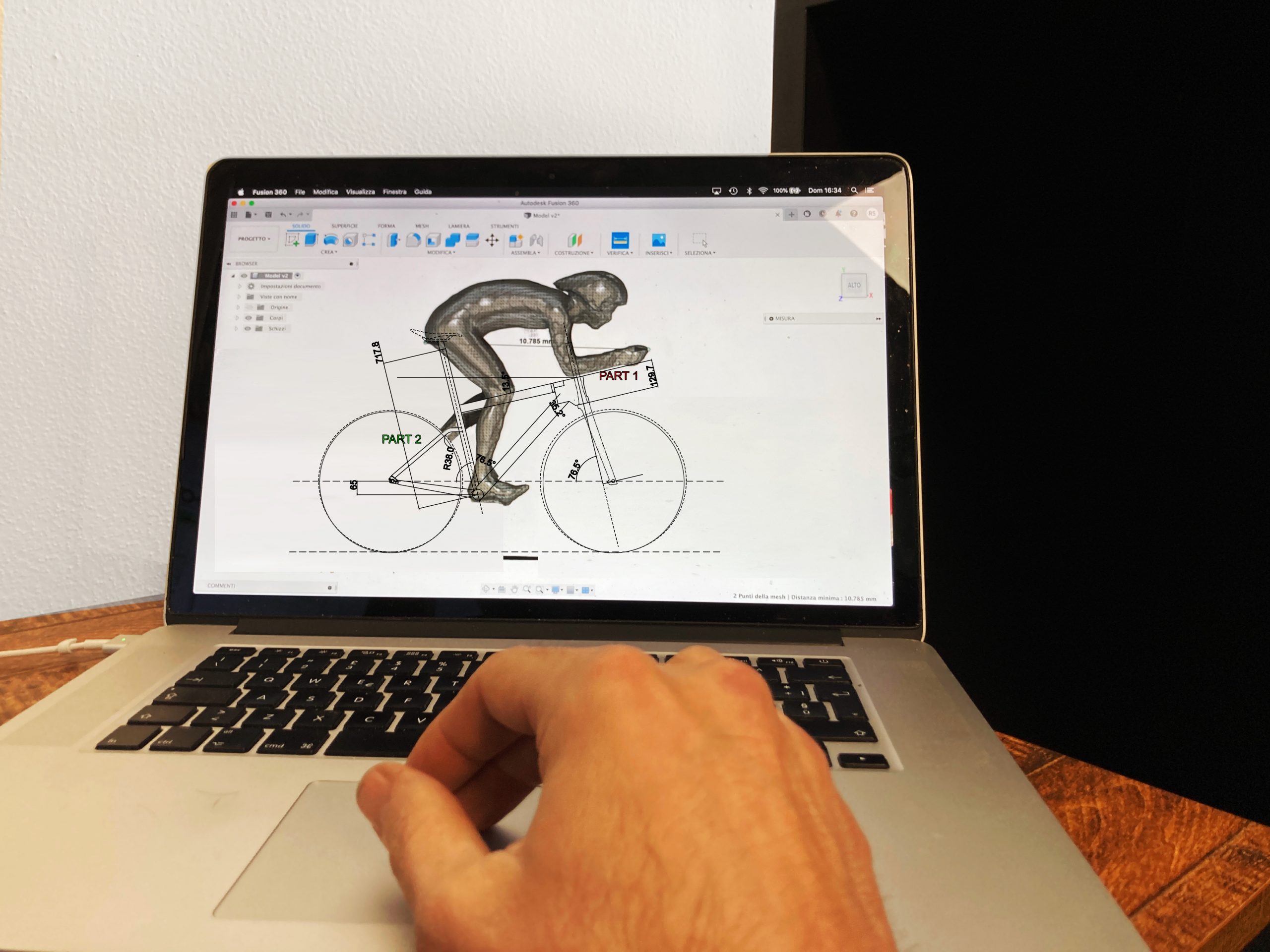

Designing around athlete's biodynamic reality.

Technical optimization that eliminates real-world compromises

The real world forces tall athletes into absurd compromises: small frame for stiffness, aggressive seatpost position, mountains of spacers to raise the front end. Result: shortened bike, unstable handling, mechanically and aerodynamically compromised performance.

Isn’t our style ;.)

High stack, improved stiffness, maximized best performance comfort zone.

THEFALCON400 is the design solution that eliminates this chain of compromises through specific technical optimization.

Solutions looking for problems.

Tall athletes with traditional frames must choose between structural stiffness and optimal positioning.

The T23 HS fork resolves this dilemma by providing 40mm additional stack without spacers, maintaining stability and correct proportions.

The integrated THEFALCON400 solution:

- LSST geometry: Optimal structural stiffness without the typical penalties of traditional large frames.

- Headbox + modular stem system: Angles from -8° to +35° plus custom 3D configurations (HSTEM, THEBLADE) to optimize stack/reach without aerodynamic compromises.

- HS T23 Fork: T23 HS fork enables 40mmhigher hand’s stack maintaining identical front triangle dimensions.

- HARPER parametric cockpit: Perfect adaptation to athlete proportions without forcing inefficient positions.

- Optimized downwash management: Athlete height becomes fluidynamic advantage through intelligent airflow management between torso and frame.

Tall athletes finally achieve biodynamically optimal position with maximal aerodynamic efficiency, eliminating the compromises that the real world traditionally imposes.

This isn’t compromise. This is technical optimization that transforms biodynamic characteristics into performance advantages.

The central downwash effect, combined with uncompromised positioning, transforms height from design limitation into aerodynamic efficiency element.

Complexity re-volution changing the rules

Why physics works for tall athletes:

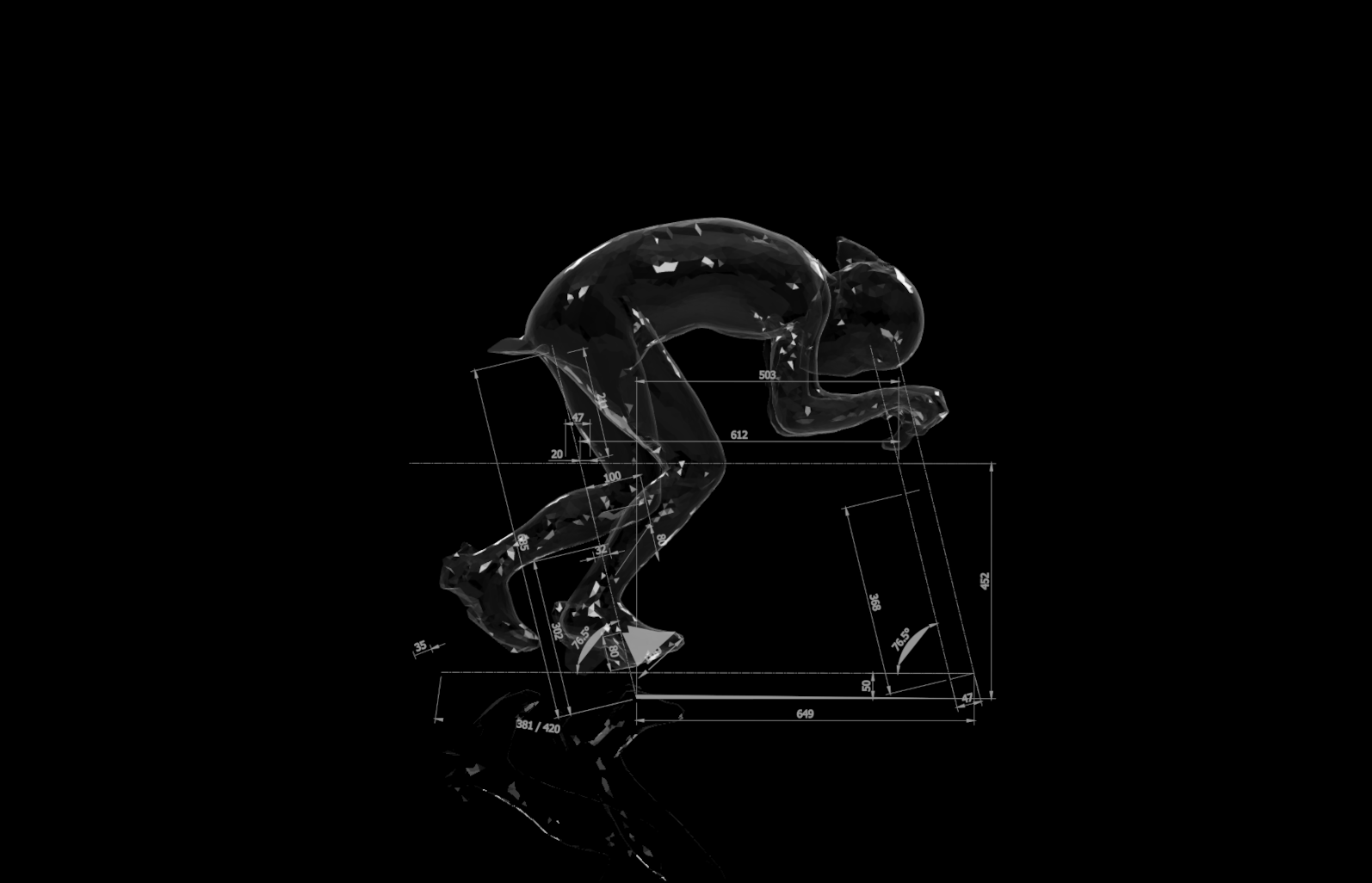

- Optimized comfort/drag balance: Digital triplet study (CFD + wind tunnel + track testing) proves that for athletes over 1.85m, well-managed downwash effect produces drag reductions superior to frontal area optimization alone.

- Maximized structural stiffness: Torsional stiffness grows with third power of tube length in closed structures. THEFALCON400 designed to maximize stiffness-to-weight ratio specifically for tall, powerful athletes.

- Improved efficiency: Tall athletes finally get comfort, stiffness and aerodynamics without compromise – impossible with traditional geometries.

Aerodynamic Permeability

In the world of track racing, performance has long been the result of a complex equation.

For decades, the aerodynamic variable has been addressed with an incremental approach: optimizing airfoils, integrating components, and reducing frontal area in a continuous search for marginal gains.

With the THEFALCON project, TOOT Engineering rewrites the foundations of this equation, introducing a radically new paradigm: aerodynamic permeability. The objective is no longer to merely minimize an obstacle, but to transform the athlete-bike system into an active aerodynamic duct.

A radical aero philosophy

The inspiration to subvert convention comes from the analysis of extreme solutions, such as those adopted by the record-breaking WMC250EV prototype. This vehicle does not simply slice through the air; it ingests it through a central macro-duct (V-Air), transforming frontal pressure drag into thrust. It is the demonstration that a moving body can become permeable to the flow.

TOOT Engineering’s designers have distilled the essence of this philosophy, not to replicate its form, but to apply its fluid dynamic principles to the unique symbiosis between a cyclist and their bicycle, creating a multi-stage flow management system.

The Wide-Stance fork design as a flow conditioner

The Problem: Turbulence from the Front Wheel The first and most chaotic source of aerodynamic drag after the initial impact is the turbulent wake generated by the rotation of the front wheel. In traditional configurations, this “dirty” airflow directly hits the athlete’s legs and the frame—the areas with the highest potential for drag.

The Solution: The Generation of Controlled Outwash THEFALCON’s fork is not a passive component. Its “Wide-Stance” architecture and the airfoil NACA design acts as an active flow conditioner. Its optimized blades intercept the turbulent air shed by the wheel and deliberately direct it outwards, generating a controlled “outwash”. This process clears a path of cleaner, less energetic air for the athlete’s lower limbs, managing drag at its source rather than passively succumbing to it.

The athlete as an active aerodynamic component

The Role of Biodynamic Geometry Once the lower flow is conditioned, the system activates its most innovative stage. THEFALCON’s frame geometry, characterized by an extended reach and a low stack, is not designed to compress the athlete into the smallest possible position. On the contrary, it is engineered to transform the human body into the most crucial aerodynamic component of the system.

The Athlete-Generated Venturi Channel This biomechanical architecture promotes a position where the athlete’s torso is strategically elevated, creating a defined channel between the chest and the bicycle’s horizontal structure. This space, far from being an imperfection, is the heart of the design. It functions as a pressure relief valve, preventing the formation of a pocket of stagnant high-pressure air against the chest. The air is channeled and accelerated through this “human tunnel,” with a dual and radical result:

- Pressure Drag Reduction: The primary cause of frontal resistance is drastically diminished.

- Active Wake Management: The accelerated flow emerging from under the body energizes the trailing wake, reducing its size and pressure deficit.

Digital triplet validation

Software simulations + Wind Tunnel + Track Testing = Scientific certainty

THEFALCON400 development used digital triplet method to validate every aspect of fluidynamic design:

- Software simulations: Precise modeling of downwash effect and torso-frame integration for athletes of different heights.

- Wind tunnel: Physical validation of CFD simulations with dynamic mannequins and real athletes.

- Track testing: Definitive confirmation of race-condition performance with elite athletes.

Result: THEFALCON400 isn’t based on theory or hope, but complete scientific validation of fluidynamic efficiency for tall athletes.But hour of tests and racing in real world are the only proof we love.

Aero is not enough to be the fastest.

THEFALCON400’s tube shape represents intelligent design based on real data rather than theoretical optimization.

"Aerodynamics is the crutch of those who cannot express the power of the engine."

Ferrari understood something profound: aerodynamics isn’t about CdA numbers, but about creating conditions where power can be fully expressed. Having an “aero” bike means nothing if you can’t put the horses to the ground.

The confusion between “aero” and “fast”:

Today’s cycling confuses theoretical aerodynamic efficiency with real speed. What wins races isn’t the lowest CdA number, but the optimal balance between power expression and resistance reduction – both air resistance and mechanical friction.

Ferrari wasn’t dismissing aerodynamics. As a designer (not just engine builder), he understood that a motor can generate power, but expressing that power is infinitely more complex. It passes through transmission, friction, structural integrity – the complete system that transforms power into velocity.

Ferrari didn’t want one more horsepower on the test bench – he wanted to win races by putting his drivers in position to express the engine’s power. This doesn’t exclude air resistance management, but integrates it with the total reality of performance.

*Enzo Ferrari

Numbers that actually matter:

In isolation, an airfoil seat tube can be 1.1% more efficient than cylindrical. But with a 180cm athlete in real position, this delta becomes less than 0.2% on overall drag.

Meanwhile, cylindrical seat tube provides:

- 16% improvement in stiffness-to-weight ratio

- Optimal performance with seatpost extensions over 300mm

- Predictable force management for powerful athletes

THEFALCON400 design privileges real advantages: for tall athletes generating high power, structural stiffness counts infinitely more than decimal aerodynamic improvements in theory.

This is applied design intelligence: optimize for athlete reality, not laboratory numbers.

Two expressions of radical speed

The “X”philosophy remains constant—designing around your human engine and bodywork. The choice is how: maximum 3D freedom or strategic hybrid precision.

Both paths lead to the same radical transformation. The X23 delivers radical speed through two strategic approaches. SWANIGAMI maximizes every additive manufacturing possibility, CHALLENGE applies advanced technologies exactly where they create maximum impact.

Same revolutionary performance, different paths to perfection.

THEFALCON 400 LS

- LSST geometry + T23 LOW Stack fork

- Optimized downwash effect for athletes over 1.75m

- HARPER TRACK parametric cockpit (option)

- Coaxial Ti/Al seat tube for 16% stiffness-to-weight improvement

- Strategic Scalmalloy 3D printing at critical points + proven AlScaZir

- Digital triplet validation – CFD, wind tunnel, track

- Build-to-order – zero waste, maximum personalization

- A.D.A.P.T. custom geometries consultation included

For tall athletes seeking real aerodynamic efficiency through intelligent fluidynamic design. Pioneering speed at human scale.

Omnium Frameset (Frame TOOT 001, Seatpost and Fork TF02) | €4.900 + VAT

CUSTOM PARAMETRIC FRAME SIZES AVAILABLE – A.D.A.P.T. PERFORMANCE FITTING INCLUDED

CONTACT US FOR MORE INFO ON THE BIKES AND PURCHASING OPTIONS

THEFALCON 400 HS

- LSST geometry + T23 HIGH Stack fork – 40mm additional stack without drag penalty

- Optimized downwash effect for athletes over 1.85m

- HARPER TRACK parametric cockpit (option)

- Coaxial Ti/Al seat tube for 16% stiffness-to-weight improvement

- Strategic Scalmalloy 3D printing at critical points + proven AlScaZir

- Digital triplet validation – CFD, wind tunnel, track

- Build-to-order – zero waste, maximum personalization

- A.D.A.P.T. custom geometries consultation included

For tall athletes seeking real aerodynamic efficiency through intelligent fluidynamic design. Pioneering speed at human scale.(option)

Omnium Frameset (Frame TOOT 001, Seatpost and Fork TF02) | €4.900 + VAT

CUSTOM PARAMETRIC FRAME SIZES AVAILABLE – A.D.A.P.T. PERFORMANCE FITTING INCLUDED

CONTACT US FOR MORE INFO ON THE BIKES AND PURCHASING OPTIONS

"Theory is never enough for those perfection addicted"

THEFALCON 400 proved that being pioneer doesn’t mean sacrificing performance. Opposite: understanding tall athlete fluidynamics first created unmatched competitive advantages.

Felix Ritzinger, James Gardner, Aaron Gate didn’t choose THEFALCON400 for technological sentiment. They chose it because downwash effect, LSST geometry, and integrated body-frame design work better for their bodies and performance.

Pioneer became standard: what THEFALCON400 demonstrated in 2022 today defines how bikes for tall athletes should be designed.

Real victories, real athletes, real physics

PROVEN TRACK PERFORMANCE

James Gardner – New Zealand National Omnium Champion 2025 Dominates individual and team pursuit, proving THEFALCON400’s multi-disciplinary versatility.

Felix Ritzinger – Six Days Berlin: “At 1.95m, I never believed I could say a bike was incredibly stiff. THEFALCON400’s LSST geometry gives me power transmission impossible with traditional frames.”

Axel Salvadori – National Individual Pursuit Champion Multiple victories including prestigious Four Nights of Geneva U19 title.

Factory Team Success 2021-2023: THEFALCON400 dominated three seasons of World Championships and Six Days competition, proving reliability and consistent performance at highest levels.

Definitive validation: When elite athletes choose THEFALCON400 for their most important goals, they’re not experimenting – they’re choosing proven speed.

CONTACT US FOR MORE INFO ON THE BIKES AND PURCHASING OPTIONS

Romolo Stanco after his experiences at the CNR of Lecco, accepts the challenge of creating in Italy a lab that develops products from innovation and research projects.

Thesignspeaking.com

Romolo Stanco who directs TOOT Engineering works on exclusive manufacturing processes that combine technology and craftsmanship.

Road Bike Action

Knowledge comes from research, tests, relationships with pro–cyclists with deep competences and design abilities in order to create something new.

Gearminded.com