HARPER TRACK®

The first track handlebar system UCI compliant 2027

It's not about size.

The 2027 regulations introduced dimensional constraints on handlebar width. Where others saw limitations, we saw a question worth answering:

What does a truly safe and performant cockpit look like at 60 km/h in bunch racing?

With dimensional parameters fixed, we could finally isolate what actually matters for control, stability, and rider confidence when positions are aggressive, speeds are extreme, and margins are zero.

HARPER is the answer to that question.

Control first, aerodynamics is a consequence.

HARPER redefines handlebar design through parametric geometry that adapts to athlete requirements while optimizing stability, control, and aerodynamic position. Patent-pending system eliminates compromise between fit and performance.

Design by TOOT Engineering | Developed with Bianca Advanced Innovations & University of Pavia CompMech Laboratory.

Proven in competition.

NOW AVAILABLE! TITANIUM 3D PRINTED AND CARBON VERSION

Everything you've ever imagined on a wheel has been rewritten by the designers and engineers of TOOT RACING ENGINEERING with the support of Bianca Advanced Innovations and COMPMECH of the University of Pavia.

Why Track Handlebars Needed Rethinking

Traditional track handlebars force compromise. You choose stack and reach based on stem length and angle, then adapt your position to what the handlebar allows. Wrong order.

2027 regulations introduced width limitations that further constrained design options. Most manufacturers responded by simply narrowing existing geometries. We saw an opportunity.

What if the handlebar adapted to the athlete instead of the other way around?

A patented solution to improve control and stability

HARPER's patent-pending parametric system allows continuous adjustment of hand position relative to stem clamping area while maintaining structural integrity and safety without connection bolts and aerodynamic efficiency.

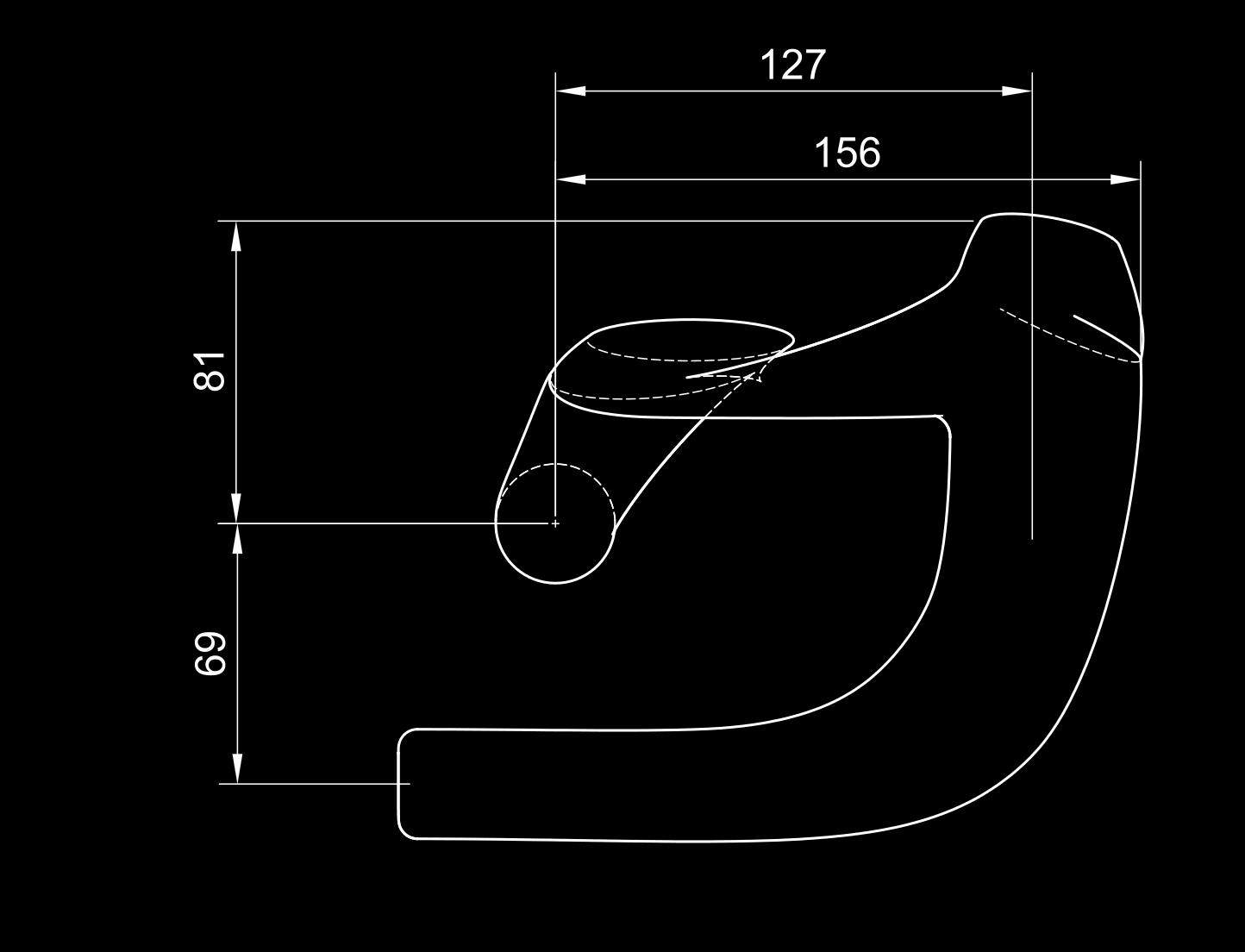

How it works: The BWS design - necessary for madison grip - becomes a parametric element. Distance between upper and lower planes can be optimized per athlete without changing stem size or angle.

Result:

- Same stem geometry fits multiple positions

- Stack and reach independently adjustable

- Maintains consistent structural characteristics

FULLY UCI COMPLIANT 2027

Fight for your minds.

2027 UCI legal track handlebars. A parametric patented design made in carbon fiber or 3D printed. Another radical revolution by TOOT Engineering team for those chasing dreams and wanting to make them real.

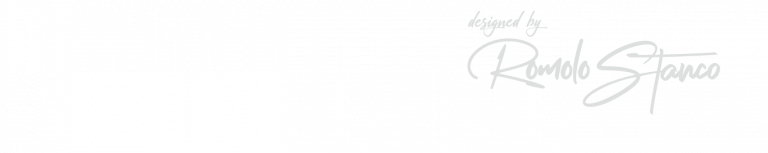

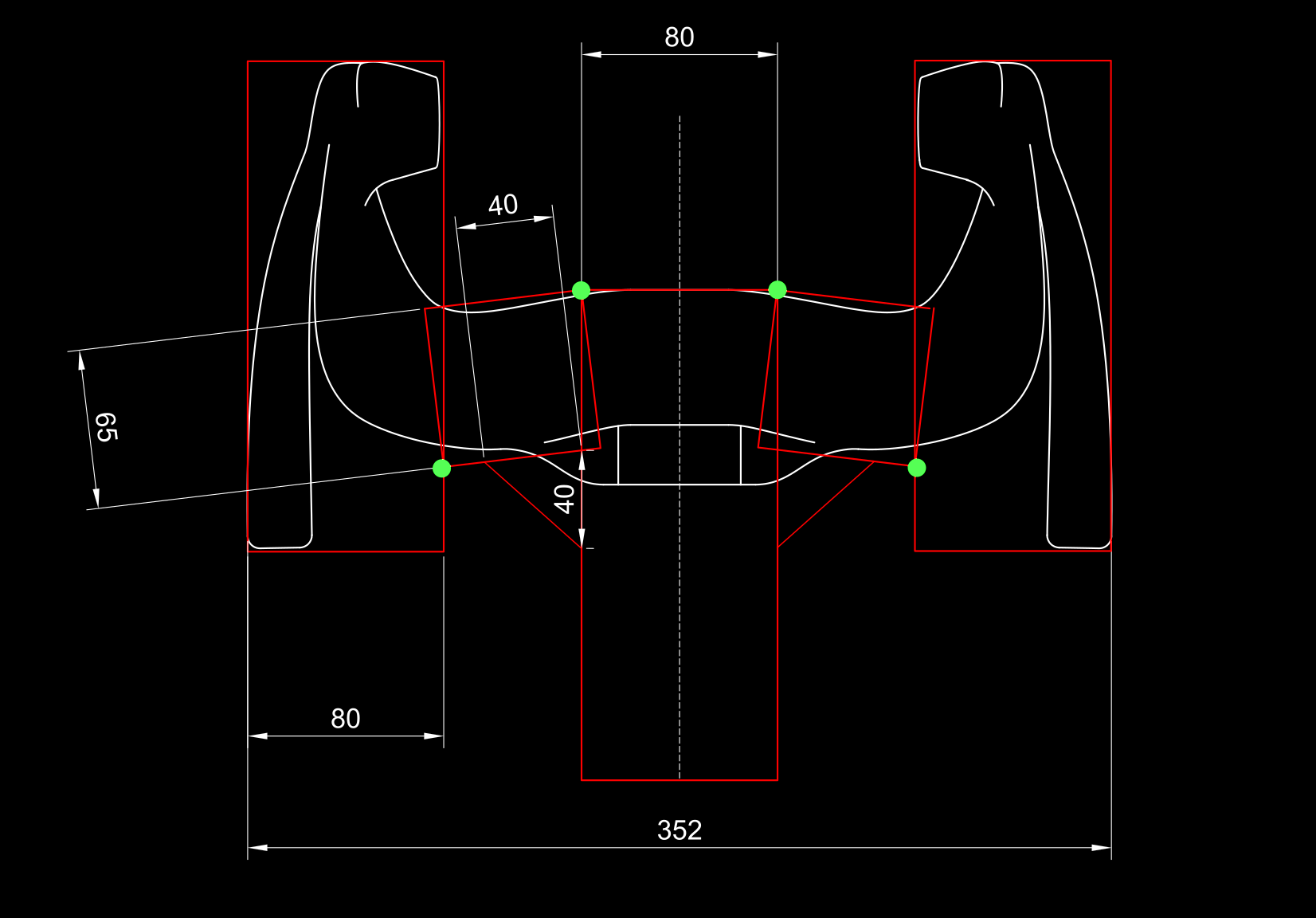

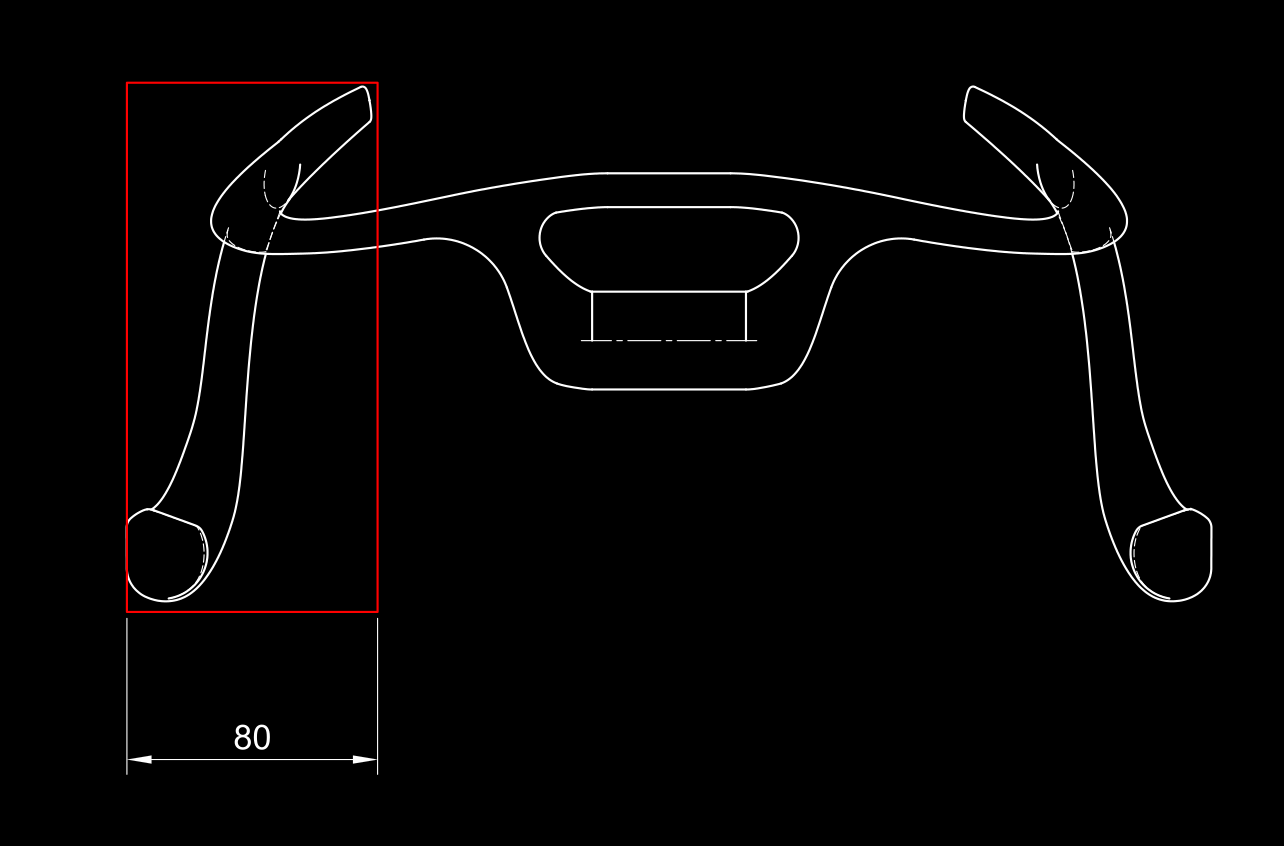

The Boxes

The cockpit which comprises the handlebar and the stem must be able to fit entirely within

the template formed by five rectangular boxes and the compensation triangles as shown by the diagram. The boxes must be placed in the plane orthogonal to the axis of the steerer

tube, passing through the highest point of the stem.

The sections

In addition, all handlebars must conform to the following:

- The maximum dimension of the cross section of the handlebars is 80 / 65 mm for track,

- The maximum dimension of the cross section of the stem is 80 mm

- The minimum dimension of the cross section of all fork accessory is 10 mm

- Two isosceles compensation triangles with two 40 mm sides are authorised at the

joints between the stem and the handlebars.

- The minimum overall width of handlebars, measured from outside to outside, is 350 mm for track

- The maximum dimension from the external extremity of the handlebar and the internal

extremity of the same side of the handlebar shall not exceed 80 mm for track.

Multiple elements are authorized for the stem, the traditional handlebars and base bars.

Individual tubes and multiple tubes have to respect the maximum permitted section

dimension of the area and the minimum section dimension of 10 mm. The multiple elements

rule applies in the same areas than the rule of the minimum and maximum dimension for the

tubes.

In the case of the traditional handlebars if one of the sections comprises multiple elements

(not greater than 2), each element taken individually have to respect the maximum and

minimum dimensions authorised in any direction. The requirement for the elements to

respect the maximum and minimum dimensions in any direction in conjunction is not

required.

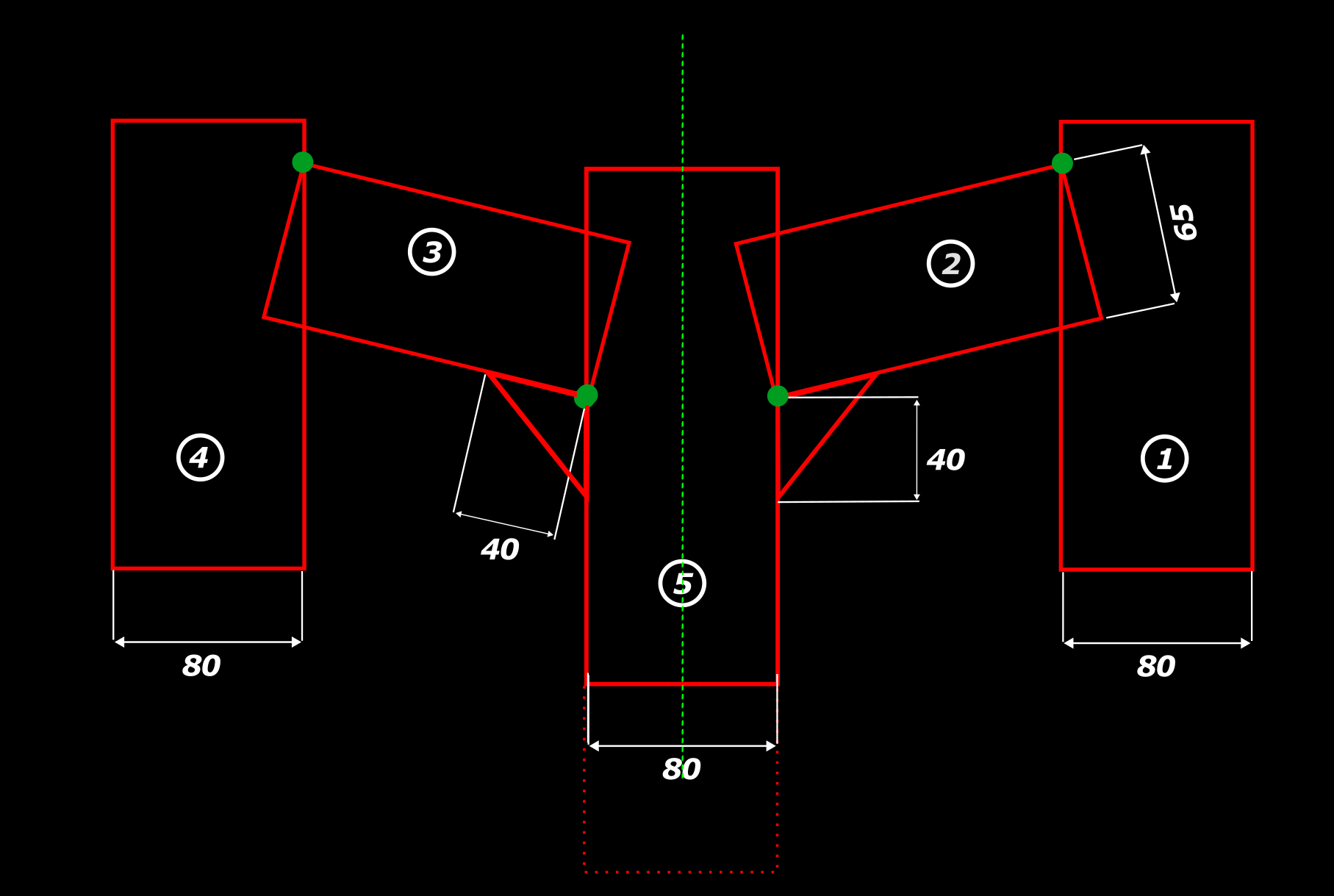

The areas

In competitions other than those covered by article 1.3.023, only the traditional type of

handlebars may be used.

The handlebars must be positioned in an area defined as follows: above, by the horizontal plane of the point of support of the saddle (B); below, by the horizontal plane passing 100 mm below the highest point of the two wheels (these being of equal diameter) (C); at the rear by the axis of the steerer tube (D) and at the front by a vertical plane passing at horizontal distance of 100 mm from the axis of the front

wheel spindle (see diagram «Structure (1A)»).

Within the rules, beyond the limits.

HARPER designed for UCI 2027 track handlebar regulations (Article 1.3.022).

Key requirements:

- Box geometry constraints (5-box template)

- Width limitations

- Cross-section dimensions (10mm minimum)

- Multiple elements configuration (max 2 elements as allowed in rules)

HARPER meets all dimensional and geometric requirements as written in regulations. Compliance drawings available for technical review.

Control Where It Matters

HARPER development began with fundamental research question: what makes a handlebar stable?

Designed by Romolo Stanco staff HARPER was developed and engineered with world class athletes.

Research Partnership: University of Pavia Multi-year collaboration with CompMech Laboratory (Prof. Ferdinando Auricchio) studying handlebar stability, control response, and rider interface dynamics.

LINK > STABILITY STUDY

Key findings: Handlebar stability is a balance between stiffness, geometry, mass distribution, and how forces transfer through rider contact points.

Traditional design assumptions don't hold under narrow-width constraints.

HARPER application: Parametric system allows optimization of stability characteristics independent of fit requirements. Athlete gets their position AND optimal control response.

Laboratory verification: Testing protocols conducted at University of Pavia. Professor Auricchio: "The parametric approach allows us to optimize variables that were previously locked together."

RACE DESIGNED

Track racing isn't one position. Madison changes, sprint positioning, endurance pacing - you move constantly. HARPER geometry maintains control authority across the entire handlebar.

Aerodynamics is (just) a consequence.

Every component manufacturer has wind tunnel data. Charts showing 5-watt savings. Marketing based on decimal points.

TOOT doesn't work that way.

Our approach:

Put each athlete in position where they are the fastest, most powerful version of themselves. Then they win.

Aerodynamics is a consequence of optimal position, not the goal.

Parametric system allows position optimization per athlete without aerodynamic compromise.

You get YOUR position - the one where you're strongest, most confident, most controlled - and the aerodynamics follow naturally.

We Don't Sell CdA Numbers

Wind tunnel numbers miss the point:

- They test static positions

- They don't measure control at sprint speeds

- They don't account for rider confidence

- They don't win madison exchanges 😉

Real races aren't wind tunnels. Real races are 60 km/h in pack, split-second positioning, madison changes while fatigued, sprint launches from chaos.

HARPER optimizes for that reality.

Results speak: Rotterdam Six Day - Justus Willemsen, first race with HIS HARPER, point race winner (2nd overall in GCTC).

Not (only) because of CdA numbers. Because he had the position, control, and confidence to execute when it mattered.

That's the only aerodynamic data that counts.

HARPER Titanium 3D Paramatric

Single-piece eliminates all of that. Universal compatibility, consistent structural behavior, no fastener concerns at 60 km/h sprint speeds.

Material: Ti-6Al-4V Aerospace-grade titanium alloy. 3D printing (DMLS process) allows parametric geometry that would be impossible with tube bending or traditional fabrication.

HARPER Carbon RS / HS

HARPER SRC (carbon) available January 2025, pre-orders open now.

Standard Stackand High Stack versions.

Optimized carbon layup schedule developed with Bianca Advanced Innovations.

Stiffness improved without structural compromise.