Be faster without marginal compromises.

Aerodynamics is just a consequence.

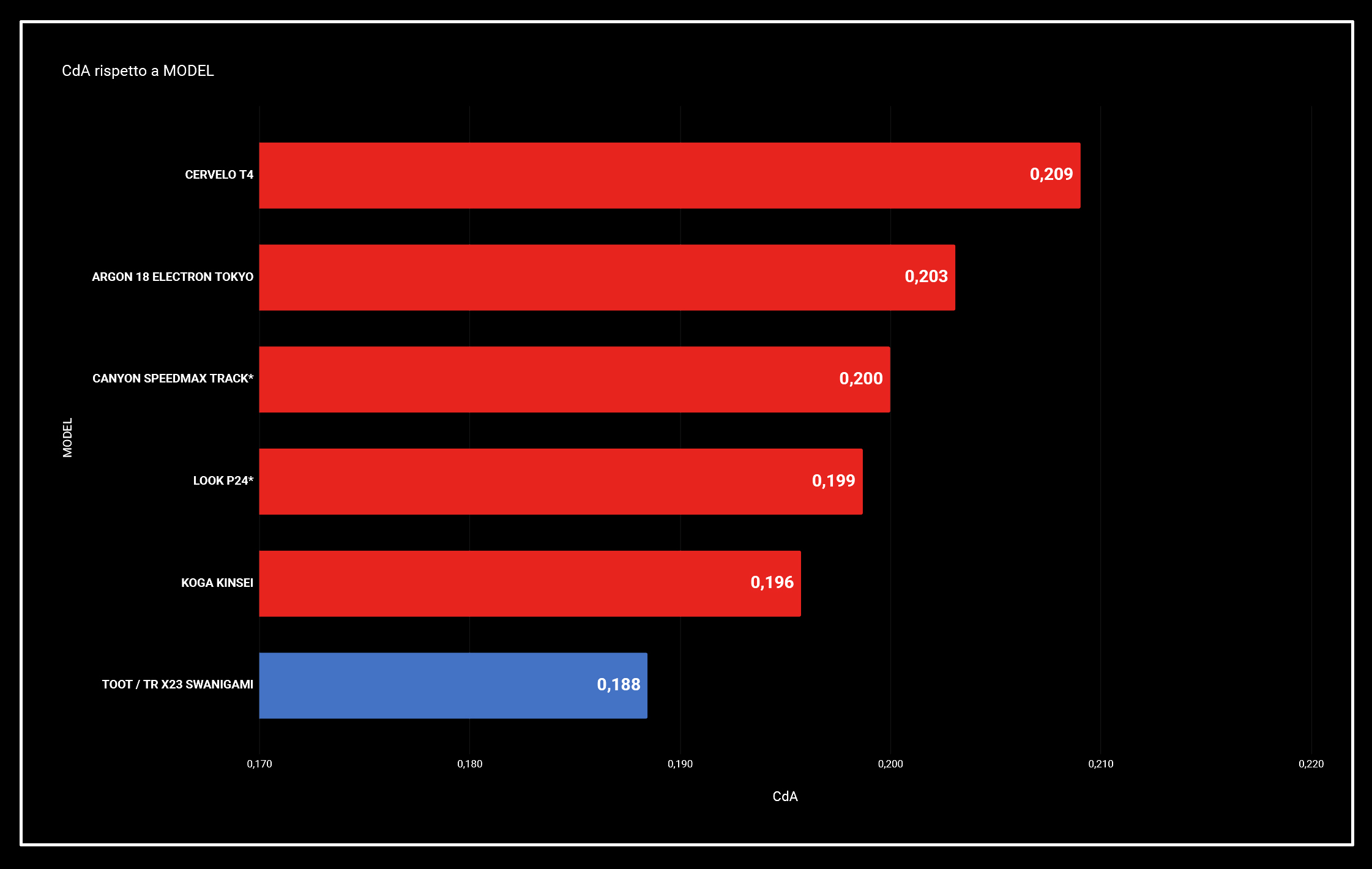

The X23’s exceptional aerodynamic performance—the lowest CdA of any current track bike—isn’t where we started. It’s the inevitable result of our revolutionary approach.

We don’t design bikes and then try to make them aerodynamic. We design the perfect bike-athlete system, and exceptional aerodynamics naturally follow.

Designing around the human engine and bodywork.

This is where we stand alone. Incomparable. Inimitable.

The old school of “marginal gains” convinced cycling that chasing isolated CdA numbers was progress. But these theoretical optimizations collapse under real-world power demands. We design around your complete performance reality: your human engine’s power signature and your body’s natural aerodynamic potential.

A bike optimized around a static wind tunnel position is useless if you can’t sustain that position at race power. We design around your dynamic equilibrium at maximum effort, where efficiency and aerodynamics unite as a single, sustainable performance system.

A.D.A.P.T. Adaptive design, advanced manufacturing.

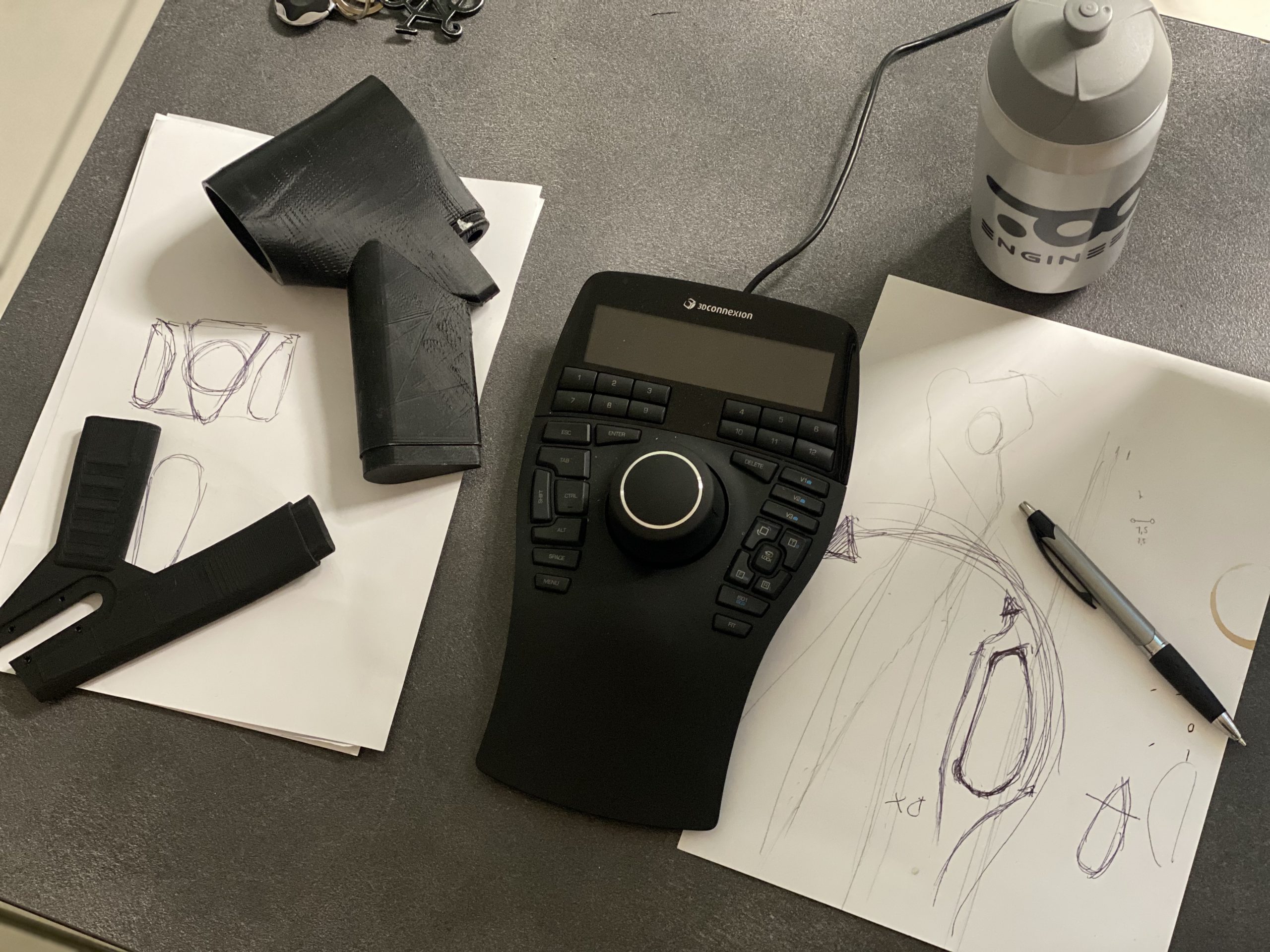

Leveraging 3D modeling, the athlete's physical form has been transformed into a digital representation based on extensive testing within a simulator. This might come as a surprise, as it emphasizes that the athlete, not the bicycle, holds the dominant role.

The X23 embodies this radical approach in its very technical DNA:

Your human engine—how you generate power, deliver torque, maintain cadence under stress—becomes the foundation. Your bodywork—your natural aerodynamic profile at race intensity—becomes the aerodynamic target. The bike emerges from this reality, not from theoretical ideals.

This isn’t customization. This is dynamic equilibrium engineering.

Every frame tube thickness responds to your real-world power transfer patterns. Every junction angle optimizes your body’s airflow at race intensity. Every geometric parameter amplifies your natural dynamic equilibrium instead of forcing you into engineered schematizations.

The result: A human-machine complex that operates as a single, perfectly integrated system. Not theoretical perfection, but real-world dominance rooted in your unique athletic characteristics and sustained performance dynamics.

As in Formula1, the simulator is the perfect partner to find the best performance zone.

The dynamic 3D scanning by Velogicfit Motion Lab acquires biometric and dynamic data while pedaling. This is fundamental to continuously control efficiency.

The simulator allows you to increase pedaling resistance in order to exactly recreate the race situations, stresses and powers.

The simulator allows you to see and monitor your instantaneous cadence.

At the same time, the 3D Aeromotion sensor reads the frontal surface and CdA in real time, allowing you to understand how the position changes when power increases. This is much more reliable than wind tunnel data where the position is held without taking mechanical resistance into account.

Once the balance between power, aerodynamic efficiency and comfort zone has been found, the cyclist is 3D scanned on the simulator to create a virtual digital twin.

By crossing the parametric model of X23 frame and components and the athlete’s best performance position, the designers redesign the parts allowing the athlete to find the most efficient position on his X23.

Why this matters for your performance?

The X23’s distinctive frame proportions aren’t accidental—they’re inspired by BMX engineering principles adapted for track cycling’s unique demands.

BMX frames excel at:

- Maximum power transmission efficiency

- Instant acceleration response

- Precise handling under extreme loads

- Structural integrity in high-stress scenarios

The X23 translates these advantages to track cycling:

- Small, stiff triangles for optimal power transfer

- Low stack geometry for aerodynamic positioning

- Oversized bottom bracket area for sprint stiffness

- Tall, narrow rear stays for acceleration compliance

This isn’t just aesthetic—it’s functional engineering that makes the bike disappear beneath you, becoming pure performance extension.

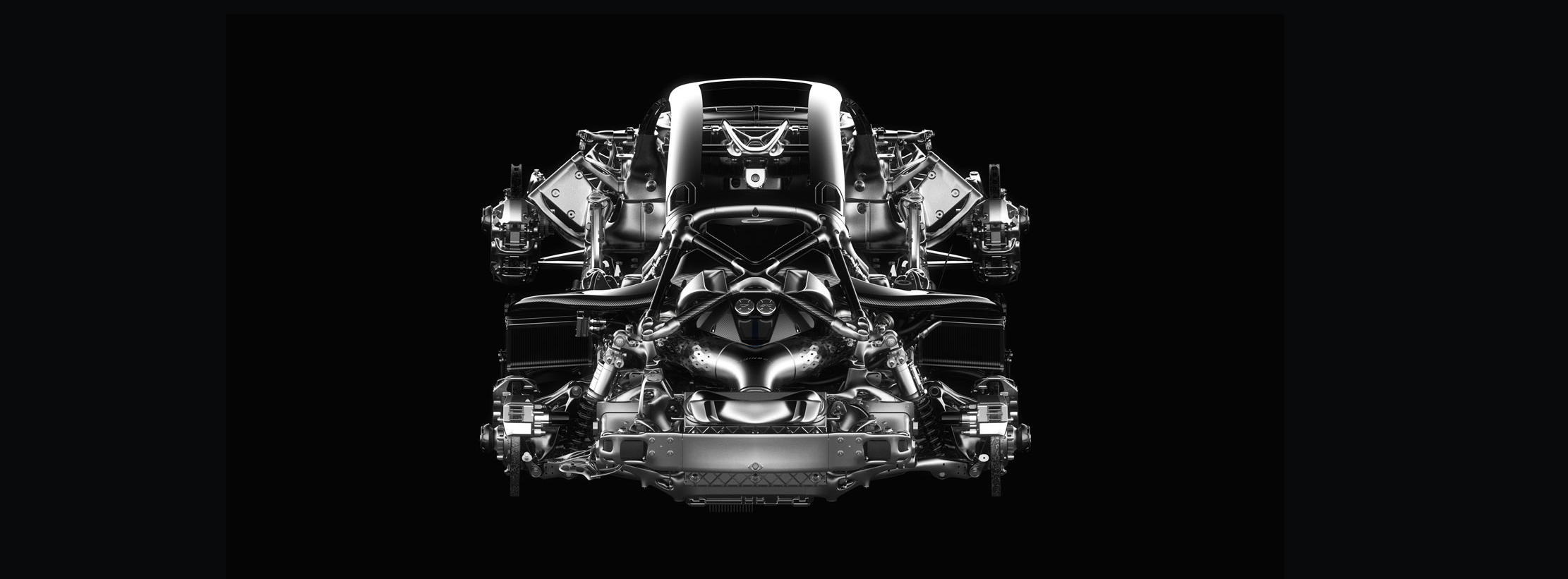

Motorsport meets cycling: Why metals win.

MotoGP bikes are aluminum. Formula 1 chassis are aluminum. The world’s fastest machines choose metal for a reason.

While cycling chased carbon fiber fashion, we learned from motorsport and aerospace. When every millisecond matters, when forces are extreme, when reliability is non-negotiable aluminum superalloys deliver.

The X23 applies this winning formula:

- 3D-printed components using aerospace-grade Scalmalloy® (developed by Airbus APWORKS)

- Precision-welded AlScaZir® tubes – our motorsport-derived superalloy

- Hand-welded assembly – no glues, no resins, no compromises

- Motorsport-level precision with aerospace-level materials.

Aerodynamics is just a consequence.

The X23’s exceptional aerodynamic performance—the lowest CdA of any current track bike—isn’t where we started. It’s the inevitable result of our revolutionary approach.

We don’t design bikes and then try to make them aerodynamic. We design the perfect bike-athlete system, and exceptional aerodynamics naturally follow.

Customized stiffness control: Unlike carbon’s directional properties, our isotropic metals deliver exactly the stiffness you need, exactly where you need it. The bottom bracket can be rock-solid while the stays remain compliant – impossible with carbon layup compromises.

Ultimate geometry optimization: 3D printing allows geometries that carbon molds simply cannot achieve. Every curve, every thickness, every junction optimized for your specific power signature and body dynamics.

Unbreakable reliability: Metal fatigue is predictable and progressive. No sudden catastrophic failures, no delamination, no temperature sensitivity. The bike that wins your biggest race will still be racing years later.

Infinite adjustability: Need a different position? Our welded construction allows post-production modifications that would destroy a carbon frame. Your bike evolves as your performance demands change.

This isn’t tradition – this is advanced engineering applied with surgical precision.

Radical efficiency through complex integrated design.

The magic happens in the integration, not the isolation.

The X23’s distinctive sharp-edged geometries aren’t styling choices—they’re America’s Cup technology applied to human-powered velocity. Like the revolutionary hull designs that dominated sailing’s ultimate competition, these edges create controlled flow separation and energy management that transforms how air moves around the bike-rider complex.

"Eagle's beak" T23 fork in two sizes

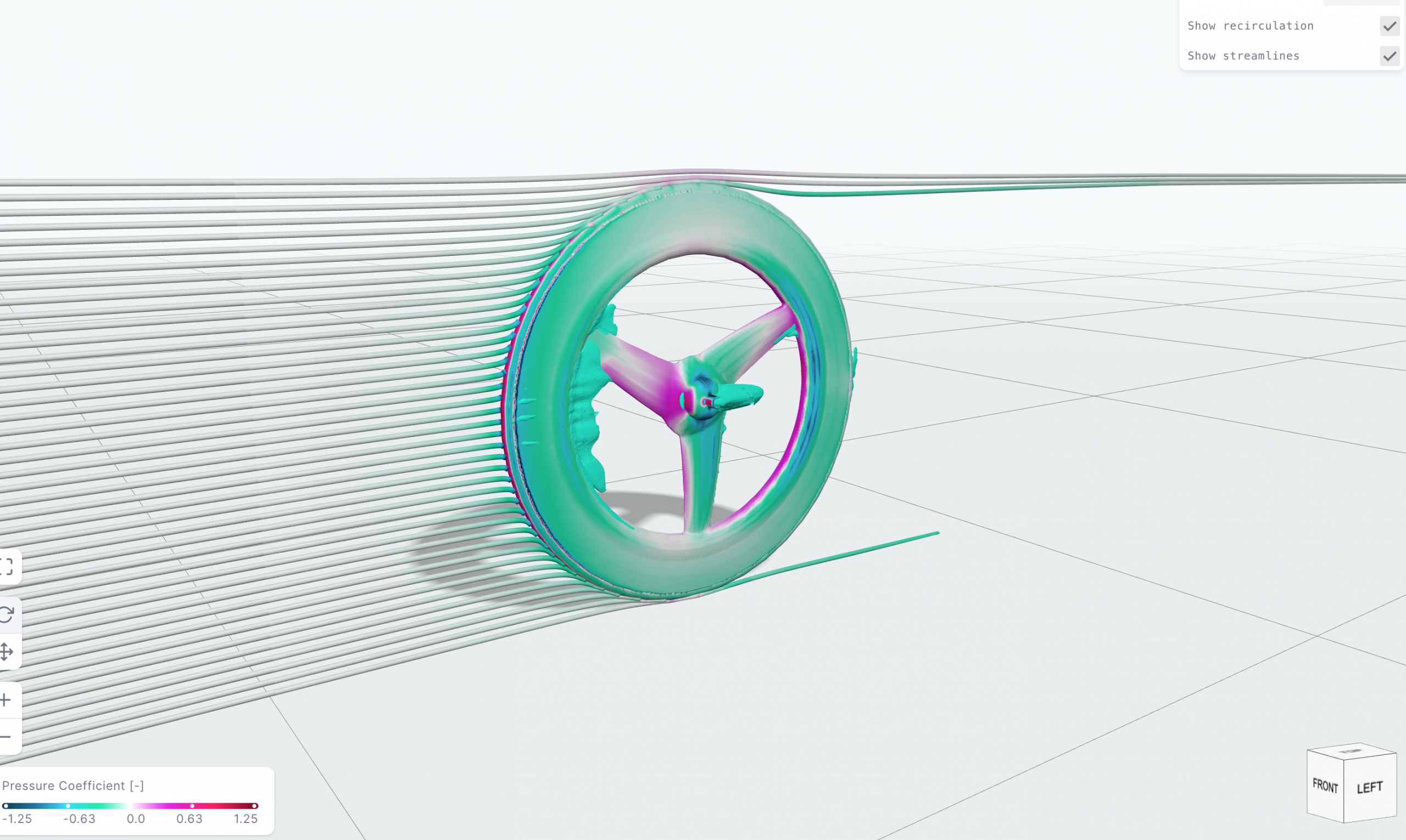

The new T23 fork (in two lengths and rakes) contributes to the customization and can count on unique precision thanks to the proximity (only 47mm distance) of the two steering bearings. The design of the fork is also the result of an aerodynamic balance between the outwash effect of the speed airflow and the optimization of the turbulences generated by the front wheel.

Why this changes everything:

Traditional bike design treats aerodynamics as a collection of optimized parts. The X23 treats aerodynamics as a unified flow-management system where every edge, every curve, every surface transition works in concert with your dynamic equilibrium.

The fork’s sharp leading edge controls upstream turbulence. The frame’s integrated transitions manage mid-body airflow. The rider’s natural bodywork completes the aerodynamic circuit.

This isn’t about adding up marginal gains from individual components. This is radical efficiency through integrated design—a complete system where aerodynamic improvements multiply rather than simply accumulate.

The aero radical improvement

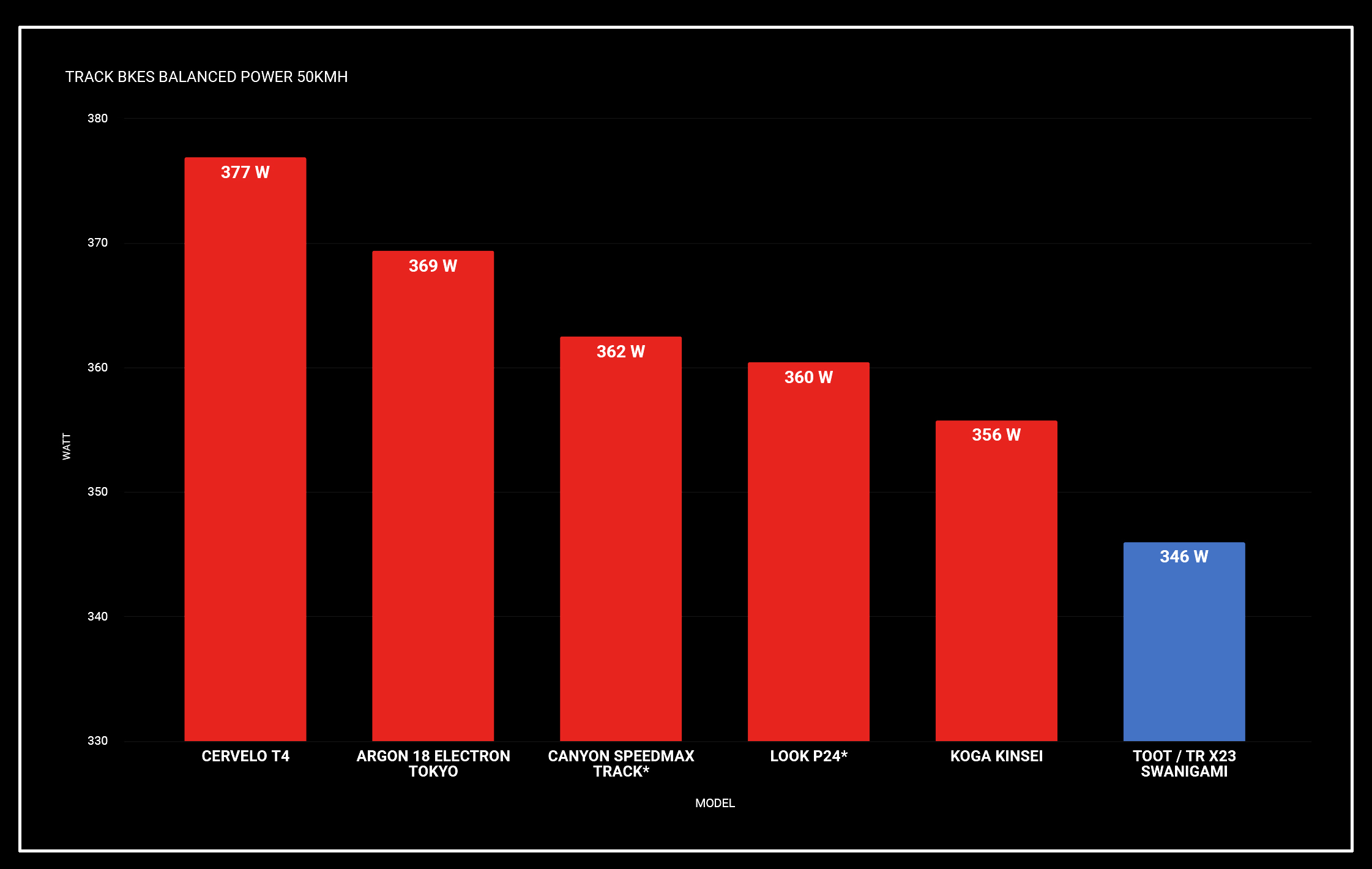

30 watts saved at 50km/h compared to traditional track frames. The aero numbers that seem impossible? They’re just the consequence of doing everything else radically right.

While others promise incremental gains, we deliver measurable transformation. The X23 doesn’t just make you faster—it makes you radically faster than your previous best self.

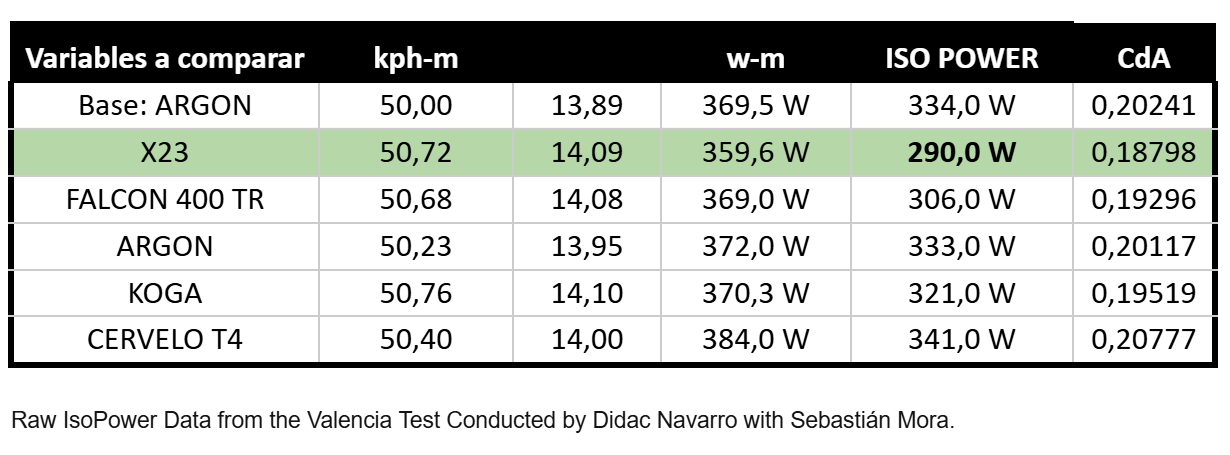

Third-party testing: Mora/Navarro validation data available

THE AERO IMPROVEMENT

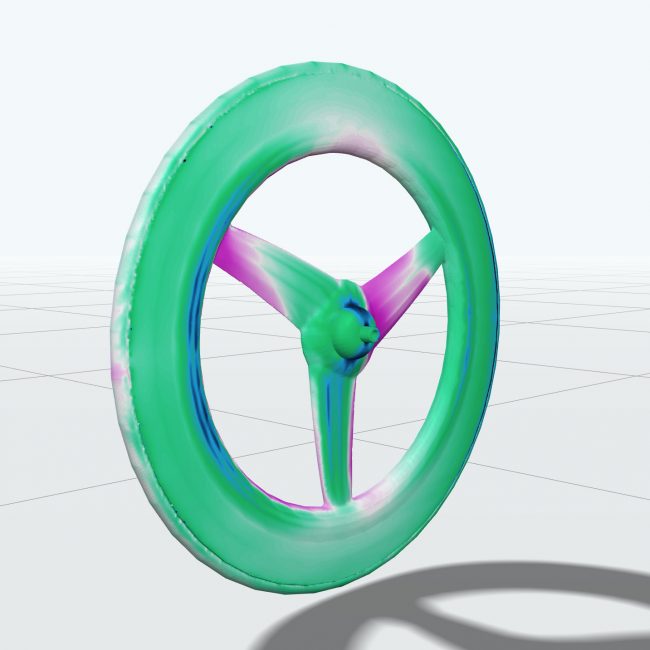

X23 SWANIGAMI is the bike with the lowest CDA of any current track bike. But this is not enough for our designers. The goal is to design a complex aerodynamic blended wing body to be faster. A low CdA bike is only the beginning to obtain the best aerodynamic performance.

Complexity is the answer

Of course, aerodynamics have a very important role in optimizing performance, but the X23 was born from the aerodynamic efficiency of the bike/athlete complex. X23 is the bike with the lowest frontal surface on the market but the real aero advantage comes from the position that the X23 allows you to maintain in the "comfort zone" with a measured watt saving of 30W at 50km/h compared to a traditional frame*.

Not recipes for speed, numbers only

The X23 frame has a maximum ground clearance of 770mm. This is impressive considering the 700C wheel diameter. Stack is 483mm only: 15% lower than any other track frame of comparable size on the market. The athlete's position is high, almost like in time trials, the result of the "best position" on the HORAI® simulator. The simulations in CFD and in the virtual wind tunnel have demonstrated a drag reduction of over 5% and an improvement in the Cd of the athlete's body.

Born to be wind

Following the wind tunnel tests in different TT position TOOT engineers defined a best bunch position to optimize the airflows and reduce drag. The athlete’s body together with the bike generates an empty channel under his body. We call this air duct T-DUCT®. The patent pending cockpit Swanigami is the key element in minimizing any element exposed to the speed airflow: the cockpit becomes a minimal support wing on which the athlete leans, transforming himself and the bike in a blended wing body.

Valencia third part real efficiency test

Efficiency comparison full paper available

Two expressions of radical speed

The “X”philosophy remains constant—designing around your human engine and bodywork. The choice is how: maximum 3D freedom or strategic hybrid precision.

Both paths lead to the same radical transformation. The X23 delivers radical speed through two strategic approaches. SWANIGAMI maximizes every additive manufacturing possibility, CHALLENGE applies advanced technologies exactly where they create maximum impact.

Same revolutionary performance, different paths to perfection.

X23 SWANIGAMI

- A.D.A.P.T. Best performance comfort zone gemetry.

- Scalmalloy 3D printed frame

- 3D printed optimized frame stiffness

- 3D printed BB T47 threaded 68mm custom options available)

- 30mm tyre clearance

- Fully handwelded and hand polished frame

- 3D printed titanium seatpost

- 3D printed 316L split seatpost optional)

- T23 Eagle’s beak fork in two sizes (low stack / high stack) thru axle 12/100

Omnium Frameset (Frame TOOT 002, Seatpost and Fork TF02) | €9.900 + VAT

CUSTOM PARAMETRIC FRAME SIZES AVAILABLE – A.D.A.P.T. PERFORMANCE FITTING INCLUDED

CONTACT US FOR MORE INFO ON THE BIKES AND PURCHASING OPTIONS

X23 CHALLENGE

- A.D.A.P.T. Best performance comfort zone gemetry.

- Scalmalloy 3D printed critical parts

- EDM wire cutting AlscaZir hollow tubes

- Machined BB T47 threaded 68mm custom options available)

- 28mm tyre clearance

- Fully handwelded and hand painted frame

- Carbon titanium seatpost

- 3D printed 316L split seatpost (optional)

- T23 Eagle’s beak fork in two sizes (low stack / high stack) thru axle 12/100

Omnium Frameset (Frame TOOT 002, Seatpost and Fork TF02) | €7.900 + VAT

CUSTOM PARAMETRIC FRAME SIZES AVAILABLE – ASK FOR GEOMETRY CONSULTANCY

CONTACT US FOR MORE INFO ON THE BIKES AND PURCHASING OPTIONS

"Theory is never enough for those perfection addicted"

From Letizia Paternoster’s golden summer at Anadia 2017 to today’s X23, our metal bikes have consistently delivered victories at cycling’s highest levels. We didn’t just participate in the evolution of track cycling—we led it.

This isn’t about building exotic showpieces. This is about creating tools that transform athletes into champions.

Every material choice, every geometric decision, every manufacturing process serves one purpose: to make you radically faster than you ever imagined possible.

The X23 represents the culmination of eight years of racing development, enhanced by the most advanced adaptive design technology ever applied to bicycle engineering.

Ready to discover how fast you really are?

Your current personal best is just your starting point.

The X23 doesn’t just make you faster—it reveals the speed that was always there, waiting for the right tool to unleash it.

Book your A.D.A.P.T. consultation and discover what radical feels like.

CONTACT US FOR MORE INFO ON THE BIKES AND PURCHASING OPTIONS

TOOT HOURGLASS® WHEELS

BEYOND THE OBVIOUSNESS. There are no "fast" wheels. We designed TOOT wheels to absorb as little of the athlete's engine power as possible. Smoothness of the bearings, stiffness, driveability, aerodynamics and low rolling resistance. The patented HOURGLASS profile and the thru-axle solution and clincher option are the way to increase your performance.

NO TIME WASTER ALLOWED

It would be ridiculous to say that the new Hourglass HG95 wheelset “is the fastest in the world”. We assure you: like a bike, the wheels do not turn by themselves, if you place them against the wall they remain still. But.

It allows you to drastically reduce absolute drag thanks to the design of the rim section optimized with CFD simulations and wind tunnel tests with the digital twin method. “It's as if the wheel isn't being hit by air” testers say, and so it is. The "hourglass" design (patented) of the rim creates an increase in air speed in the central part of the rim and consequently a decrease in pressure on the rim. This effect determines a significant reduction in aerodynamic weight and contributes to reducing CdA and making a high rim wheel extremely light and easy to handle. The second part of the “hourglass” cleans the flow towards the center of the wheel, optimizing the functioning of the spokes and the hub flange. The Compmech Engineers collaborated with the TOOT design team to balance aerodynamic optimization with increased stiffness.

Clincher optimized, tubular available

The Hourglass HG95 wheelset was designed for clincher use by increasing the internal rim channel compared to the ALIEN to accommodate 25mm (up to 30mm) clinchers: in the laboratory and in track tests this solution demonstrated lower rolling resistance and better rideability. However, it is also possible to have the HG95T with a tubular floor.

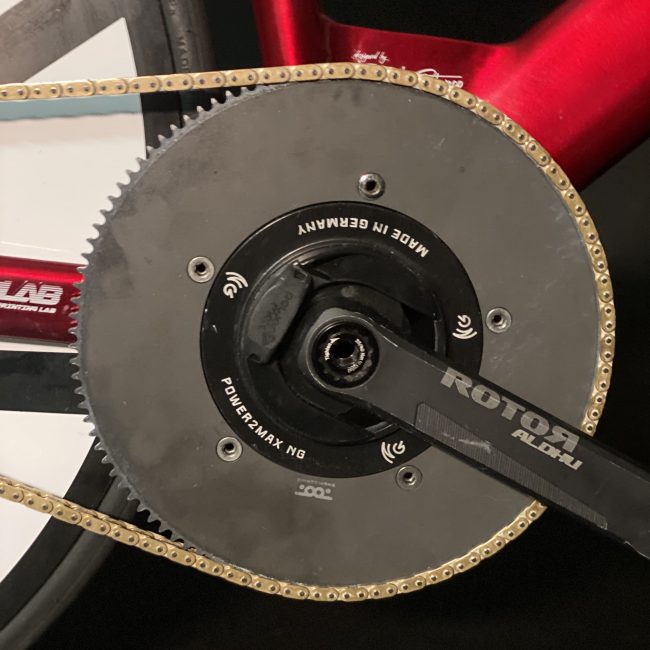

TOOT KATHENEENA® DRIVETRAIN

Watt saved with KATHENEENA® compared to a 1/2" - 1/8" track drivetrain

Test range: CdA 0,176 Speed 65Kmh gear ratio 4,12 | Power reduction 4%

Why the stayer?

The laboratory tests were carried out with advanced instruments as shown in the table above. A track test was carried out comparing the real data in motor paced track tests. The aerodynamic difference values that may be relevant in a track test to measure non-macroscopic differences become irrelevant if the CdA value becomes irrelevant. In the test behind a stayer bike at 79Kmh with gear ratio 5.36 (development 11.32 m) with KATHENEENA® the average power value stood at 250W NP cadence 114RPM (gear 118x22). With standard drivetrain the NP value with the same metric development data exceeds 280W NP with a percentage difference of 14%

IT'S NOT GAINING, IT'S NOT LOSING. Marginal gain is a misnomer. Nobody makes you earn anything, nobody increases your speed for anything. But "not losing" watts is the primary purpose of the new KATHEENEENA transmission. More than 5% advantage over a conventional drivetrain. We don't create speed but we know how to allow you not to lose it.

KATHENEENA® DRIVETRAIN. WATT SAVER

The transmission is another element of large power losses due to mechanical friction. Thanks to a test bench and the collaboration of DID chain and Csoltmester, TOOT engineers compared different chain and chainring solutions.

Same watts, more speed...

The X23 Katheneena transmission almost doubles the number of gear teeth for the same circumference. A 60x15 becomes a 109x27 and the comparison test returns a reduction in contact friction of 4%. X23 Katheneena also creates a significantly greater flywheel effect than a 1/8” drivetrain improving overall drivetrain efficiency. KATHENEENA's performance is not legitimate only from tests carried out at the University of Pavia.

Patented by TOOT Racing, developed with D.I.D

The Japanese technicians have developed a chain with a pitch reduced by 65% compared to a 1/2" - 1/8" track chain and very short links: the polygonal effect is reduced, transmission between chain and gears improves 19% reducing overall friction. The work was done in partnership with Csoltmester who developed dozens of solutions for gears, tooth geometries, chainrings, cog materials (including Ergal) and surface treatments with an exclusive lubrication.

...more speed, less friction

The drivetrain patented by Bianca Advanced Innovations was successful in a discipline where the stresses on the transmission elements are much higher than in a track race. Giuseppe Atzeni won the Swiss Stayer National Championships with KATHENEENA. Stayer or demi-fond is a discipline in which speeds of almost 90km/h are reached for an hour of racing behind the motorbike: temperatures and mechanical stresses of the transmission test durability, resistance to effort and fatigue beyond all limits, allowing the optimization of treatments, ratios, chain tension and lubrication systems.

Romolo Stanco after his experiences at the CNR of Lecco, accepts the challenge of creating in Italy a lab that develops products from innovation and research projects.

Thesignspeaking.com

Romolo Stanco who directs TOOT Engineering works on exclusive manufacturing processes that combine technology and craftsmanship.

Road Bike Action

Knowledge comes from research, tests, relationships with pro–cyclists with deep competences and design abilities in order to create something new.

Gearminded.com